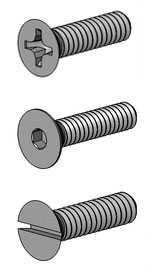

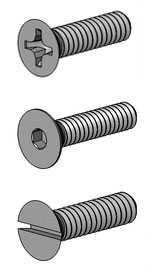

Flat head screws are characterized by having a head with a flat top and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits. Flat head screws are characterized by having a head with a flat top and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

Driver Availability

(dependant on size/material)

o Socket

o Slotted

o Phillips | Flat Head Screw Specifications

o ASME B18.3, ASME B18.3.6

o DIN 963 / ISO 2009

o DIN 965 / ISO 7046

o DIN 7991 / ISO 10642 | Flat Head Screw Sizes

o #00 - 4"

o M1.2 - M100 | | PEEK Slotted vs. Phillips Driver | Slotted Head Advantages | Phillips Head Advantages | - Slotted head screws tend to strip less than Philips, especially in harsh environments

Slotted heads are typically better in applications where it's going to be unscrewed and re-done periodically, as the head tends to wear less. In dirty environments, a flat head is much easier to clean out | - Phillips head offers a much stronger joint since it can tolerate more torque.

| Countersink Angle For most flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified. | Thread Type | Normal Flat Head Countersink Angle | UNC / UNF | 82° | | Aerospace | 100° | | ISO Metric / Imperial | 90° | | Flat Head Screw Availability Engineered Polymers Advanced Ceramics Specialty Metals |

Flat head screws are characterized by having a head with a flat top and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

Flat head screws are characterized by having a head with a flat top and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.