A Ni-Cr alloy with very good high temperature stability

Oxidization and carburization resistant up to 1400°F / 760°C

Oxidization and carburization resistant up to 1400°F / 760°C- Good corrosion resistance, which increases with the various grades

- Learn more by downloading our datasheets

Not to be confused with Inconel, Incoloy fasteners are made of a nickel alloy which contains iron and a lower content of nickel. Incoloy is essentially a more economical option to Inconel, yet with more restricted corrosion resistance and temperature limits. Typically, Incoloy is an ideal material for long-term exposure in high temperature environments due to its oxidation, carburization and creep resistance. Incoloy is widely used for its resistance to seawater, brine, sour gas and high chloride environments at elevated temperatures, which make it a popular choice in the oil and gas and power industries.

The most commonly used grades of Incoloy fasteners are Incoloy 800, 800H, 800HT; Incoloy 825; and Incoloy 925. For more indepth information on these specific grades, visit our specific web pages or contact one of our engineering experts:

- Incoloy 800, 800H, 800HT (1.4876, 1.4958, 1.4959)

- Incoloy 825 (2.4858)

- Incoloy 925

Datasheets: Incoloy 800, 800H 800HT; Incoloy 825; and Incoloy 925

Resources: Incoloy Torque Specs

Incoloy Fastener Types: Bolts, Nuts, Screws, Threaded Rods, Washers

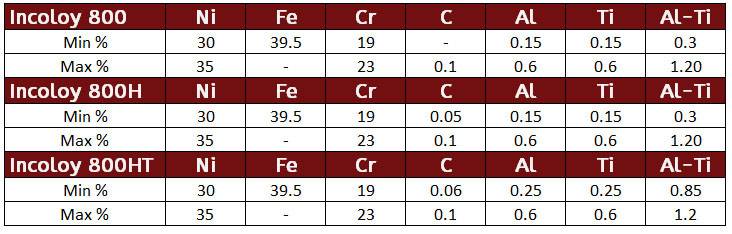

Common Incoloy Chemistry, Grades & Specifications

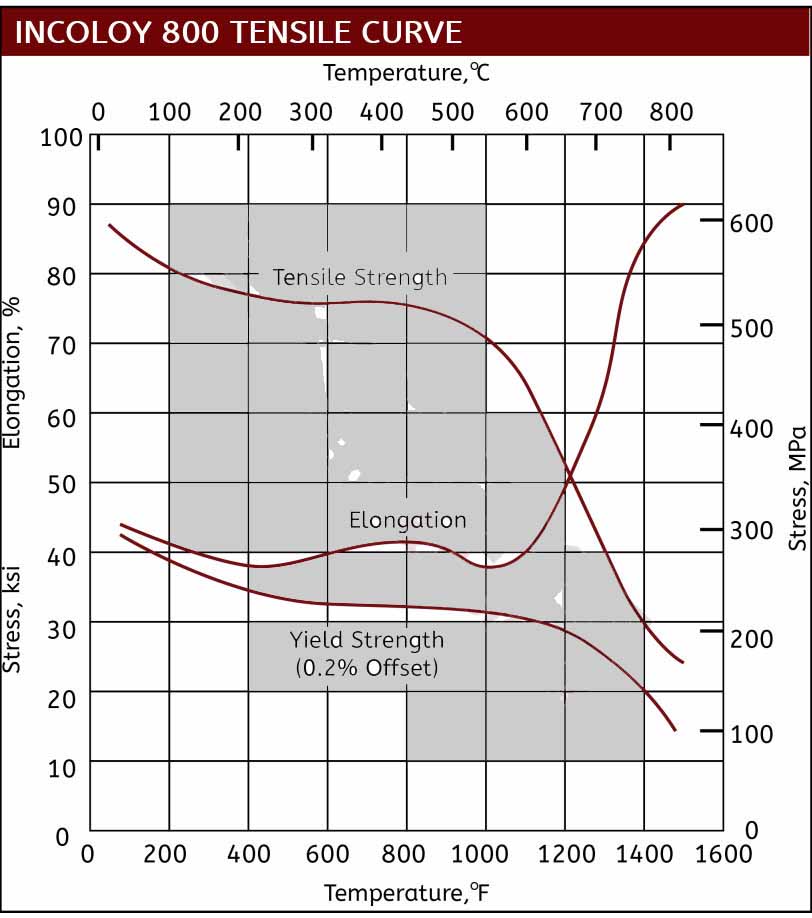

Incoloy 800, 800H, H800HT (1.4876, 1.4958, 1.4959)

Incoloy 800 series fasteners are best utilized for applications that require stable structure and good strength during prolonged exposure to high temperatures. Learn more by downloading out Incoloy 800 datasheet.

Incoloy 800, 800H & 800HT Specifications: UNS N08800/ N08810 / N08811 (800, 800H, 800HT), ASTM B408, ASME SB408, ASTM B564/ASME SB564, EN 10204-3.1, Werkstoff 1.4876 (800), Werkstoff 1.4876 H and 1.4958 (800H), Werkstoff 1.4876 HT and 1.4959 (800HT)

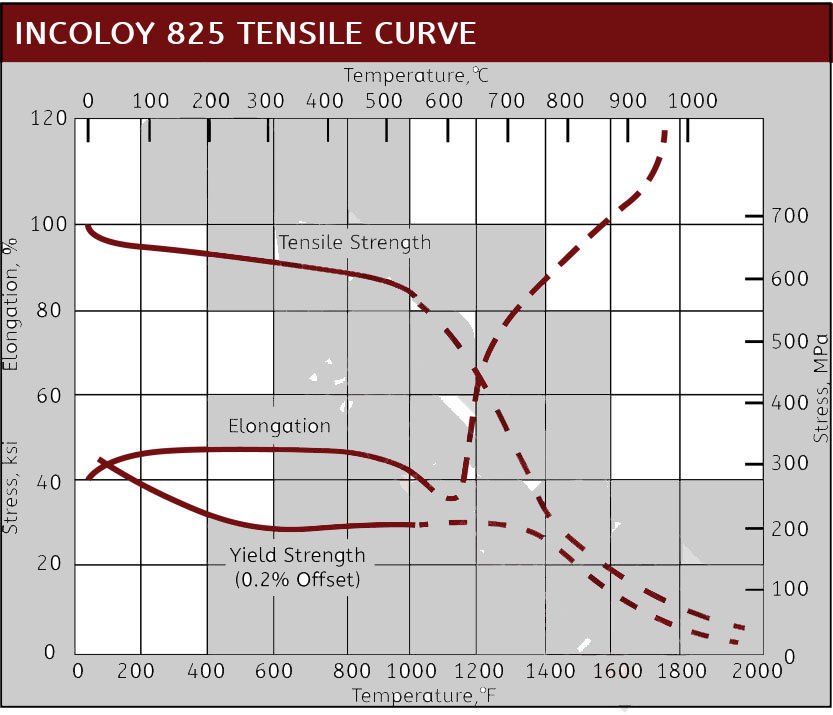

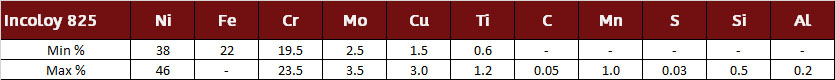

Incoloy 825 (2.4858)

Related to the Incoloy 800 series alloys, Incoloy 825 (2.4858) differentiates itself with the additional elements of molybdenum and copper, which provides it improved corrosion resistance. Learn more by downloading out Incoloy 825 datasheet.

Incoloy 825 Specifications: UNS N08825, BS 3076NA16, ASTM B 425, ASTM B 564, ASME SB 425, ASME SB 564, ASME Code Case N-572, DIN 17752, DIN 17753, DIN 17754, VdT"UV 432, ISO 9723, ISO 9724, ISO 9725, Werkstoff Nr 2.4858

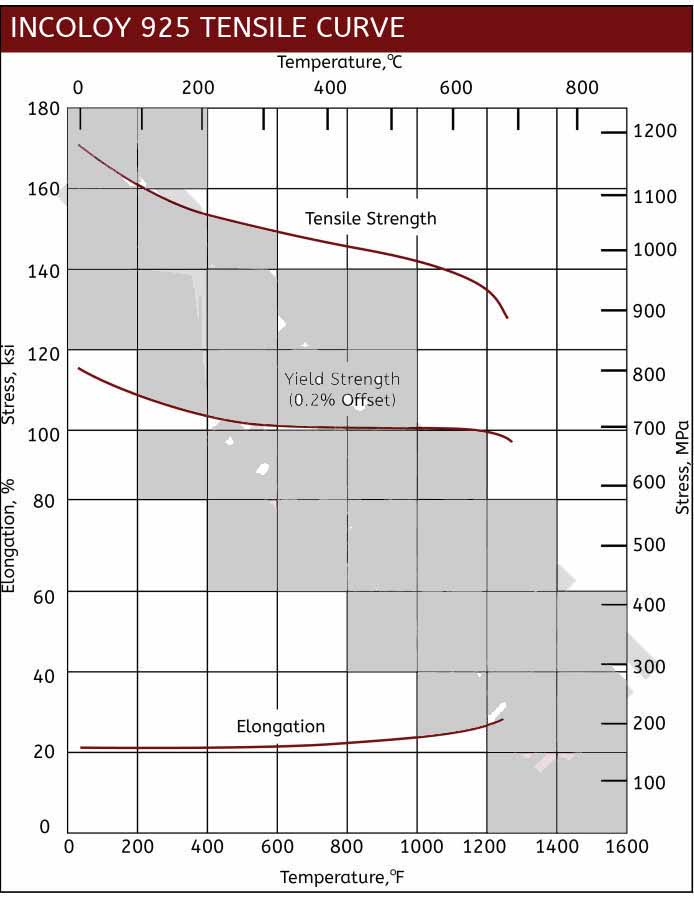

Incoloy 925

Incoloy 925 is a precipitation hardened alloy. It offers comparable corrosion resistance to it’s sister alloy Incoloy 825, but with the increased strength resulting from the age hardening process. Learn more by downloading out Incoloy 925 datasheet.

Incoloy 925 Specifications: UNS N09925, ASTM B637, NACE MR0175

Mechanical Properties of Incoloy