A Ni-Cr alloy with very good high temperature stability (1.4958, 1.4876 and 1.4959)

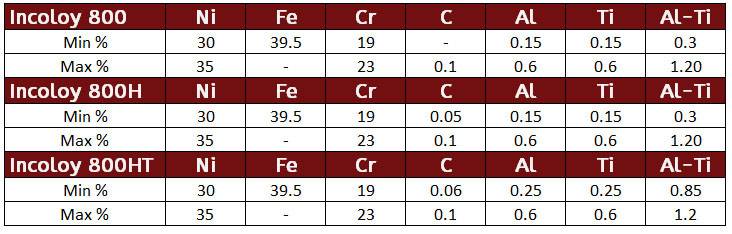

Incoloy 800 fasteners and flanges are best utilized for applications that require stable structure and good strength during prolonged exposure to high temperatures. These fasteners are utilized in a diversity of industries involving corrosive environments and high temperatures. Incoloy 800 series nickel alloys include Incoloy 800, 800H, and 800HT. All are identical except for the higher level of carbon in alloy 800H and the addition of approximately 1.20 percent aluminum and titanium in 800HT. Incoloy 800H offers improved stress rupture properties over 800. Incoloy 800HT further improves on this to ensure optimum high temperature properties. Learn more by downloading our datasheet.

Corrosion Resistance

- Good strength and excellent resistance to oxidation and carburization in high-temperature exposure

- Good high temperature strength

- High creep rupture strength

- Good corrosion resistance in many acidic environments

- Good resistance to many sulfur-containing atmospheres

Temperature Guidelines

Incoloy 800 is primarily used in applications with temperatures up to 1100° F, where alloys 800H and 800HT are normally used in temperatures above 1500°F where creep and stress rupture protection are a critical concern. Incoloy 800HT will not become embrittled even after long periods of usage in the 1200-1600° F. When exposing Incoloy 800 to aggressive media in the temperature range of 1000 to 1400°F, it can be sensitized and made susceptible to intergranular attack.

Applications

- Industrial and chemical processing industries look to Incoloy 800 series fasteners for the construction of heat exchangers and process piping, as well as carbonizing equipment and heating element sheathing.

- Nuclear power plants require Incoloy 800 for steam generators, while the pulp and paper industry needs these fasteners digestor-liquor heaters.

- Chemical and petroleum processing employ Incoloy 800 fasteners for heat exchangers and other environments containing nitric acid media, as well as for applications where resistance to chloride stress-corrosion cracking is required.

Incoloy 800 Physical Properties

- Density: 0.27 lbs/in^3, 7.94.g/cm^3

- Specific Heat, Btu/lbo°F, J/kgo°C:

- 32-212°F (0-100°C): 0.11 (460)

- Mean Coefficient of Thermal Expansion: in/in/°F (mm/m/°C) 70- 212°F (20- 100°C)– 7.9 x 10-6 (14.2)

- Thermal Conductivity: BTU/h-ft-°F (W/m-°K): 70°F (21°C): 6.7 (11.6)

- Modulus of Elasticity: ksi (MPa) 28.5 x 10^3 (196.5 x 10^3) in tension

- Permeability at 70°F (21°C) H= 200 Oersted : Annealed : 1.014

- Melting Point: 2525°F (1385°C)

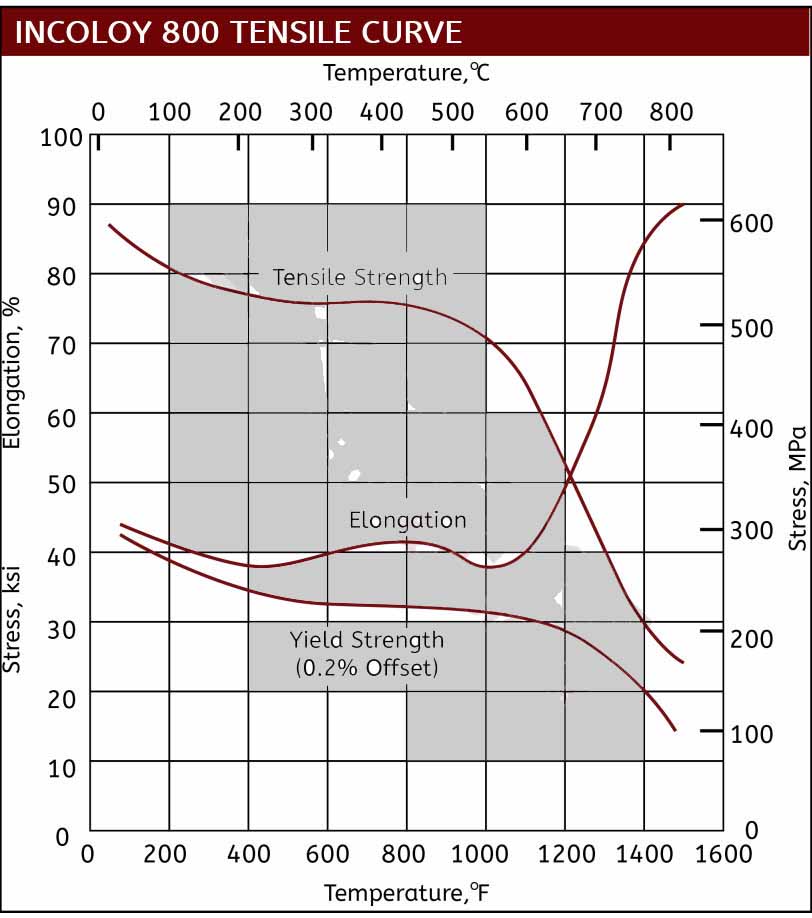

Incoloy 800 Strength Properties

- Ultimate Tensile Strength: 75 KSI min (420 MPa min)

- Yield Strength (0.2% offset): 30 KSI (gauges ≥ 0.020 inches)

- Elongation: 30% min

- Hardness: Rb 84 nom

*Annealed Typical at room temperature

Resources: Incoloy Torque Specs, Flange Dimensions, Flange Bolting Chart

Incoloy Fastener Types: Bolts, Nuts, Screws, Threaded Rods, Washers

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Incoloy 800, 800H & 800HT Chemistry and Specifications

Incoloy 800, 800H & 800HT Specifications: UNS N08800/ N08810 / N08811 (800, 800H, 800HT), ASTM B408, ASME SB408, ASTM B564/ASME SB564, EN 10204-3.1, Werkstoff 1.4876 (800), Werkstoff 1.4876 H and 1.4958 (800H), Werkstoff 1.4876 HT and 1.4959 (800HT)

Incoloy 800 Mechanical Properties