A Ni-Cu alloy with high strength and good corrosion resistance

- Excellent resistance to hydrofluoric acid

- Excellent resistance to sea water for marine applications

- High strength metal with good toughness at high temperatures

- In-depth information on grades 400 and K500

- Datasheets available for Monel 400 and Monel K500

- Socket weld flange features and benefits

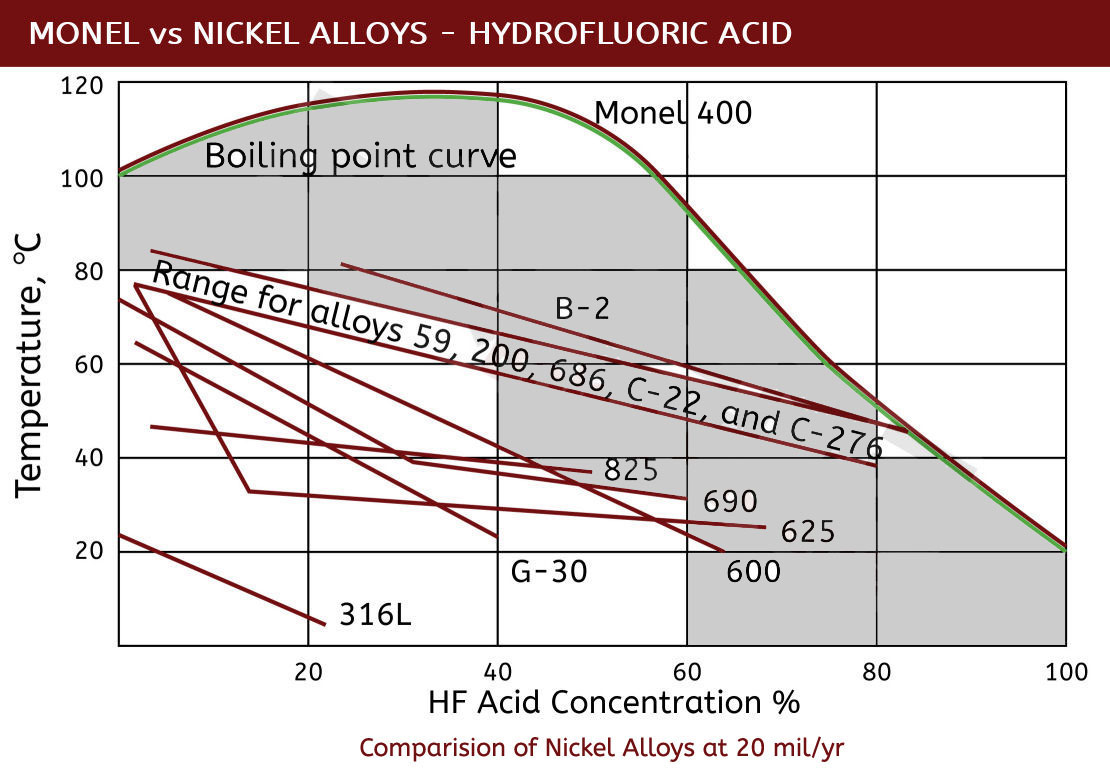

Monel(R) socket weld flanges, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel socket weld flanges is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel socket weld flanges are perhaps the most resistant of all commonly used specialty alloys.

Monel alloy 400 & K500 socket weld flanges also exhibit excellent corrosion resistance in marine applications and have reasonable corrosion resistance to sulfuric and hydrochloric acids under reducing conditions. Monel K500 socket weld flanges are over 2x as strong as Monel 400 socket weld flanges.

Because of these characteristics, Monel socket weld flanges are often found in marine and chemical processing applications.

The most common grades of Monel flanges are Monel 400 and Monel K500 . Gain more insight on these two nickel alloy grades by accessing our Monel 400 and K500 overviews or by contacting our engineering experts.

Resources: Monel Torque Spec, Flange Dimensions, Flange Bolting Chart, Monel 400, Monel K500

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Common Grades of Monel Socket Weld Flanges

Monel 400

Monel 400, UNS N04400 (QQ-N-281), is a nickel-copper alloy with high strength and excellent corrosion resistance in a range of media including sea water, hydrofluoric acid, sulfuric acid, and alkalies. Monel 400 is commonly in marine engineering, chemical and hydrocarbon processing applications.

Monel 400 Specifications: BS3075NA13 (Wire), BS3076NA13 (Bar), ASTM B 164 (Rod, Bar, and Wire), ASTM B 564 (Forgings), ASME SB 164 (Rod, Bar, and Wire), ASME SB 564 (Forgings), AECMA PrEN 2305 (Wire for Rivets), SAE AMS 4675 (Bars and Forgings), SAE AMS 4730 (Wire), SAE AMS 4731 (Wire and Ribbon), DIN 17752 (Rod and Bar), DIN 17753 (Wire), DIN 17754 (Forgings), VdT"UV 263 (Sheet, Plate, Bar, and Tubing), QQ-N-281 (Plate, Sheet, Strip, Bar, Rod, Wire, and Forgings), Werkstoff 2.4360

Monel K500

Monel K500, UNS N05500 (QQ-N-286), is a precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of Monel alloy 400 with greater strength (over 2x as strong) and hardness. It also has low permeability and is nonmagnetic to temperatures as low as -150°F (-101°C).

Monel K500 Specifications: BS3075NA18 (Wire), BS3076NA18 (Rod and Bar), ASTM B 865 (Rod and Bar), DIN 17752 (Rod and Bar), DIN 17753 (Wire), DIN 17754 (Forgings), QQ-N-286 (Rod, Bar, Wire, and Forgings), SAE AMS 4676 (Rod and Bar), ASME Code Case 1192 (Rod and Bar), ISO 9723 (Bar), ISO 9724 (Wire), ISO 9725 (Forgings), Werkstoff 2.4375

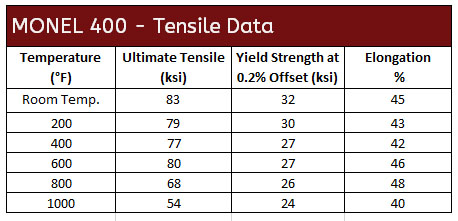

Mechanical Properties of Monel

Monel 400 Corrosion Data

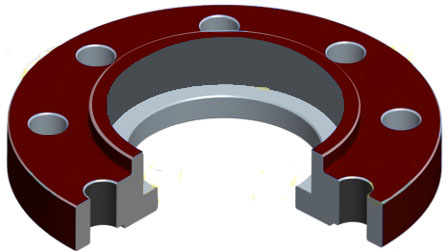

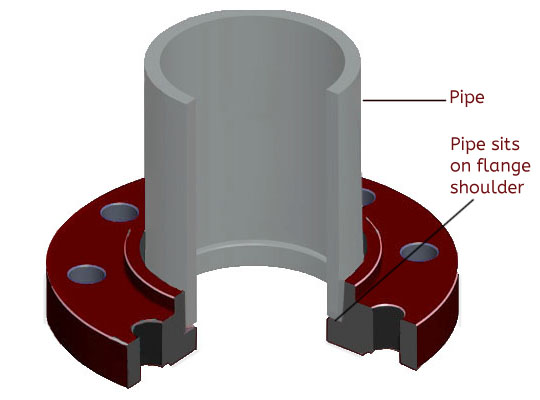

Socket Weld Flange Features & Benefits

Similar to a slip on flange, an Monel socket weld flange has an added shoulder inside the bore hole. The socket weld flange is designed so that a pipe can be inserted into the socket of the flange until it hits the shoulder of the socket. The pipe is then backed away from the shoulder approximately 1/16 inches before being welded to the flange hub. This internal weld provides this type of flange added strength. In addition, by grinding the internal weld smooth, turbulence and flow restriction are minimized. Monel socket weld flanges are most commonly used on small diameter applications (1/2" through 4") and high pressure piping systems.

Socket Weld Flange Benefits

- Best for small size, high pressure applications

- Static strength equal to a slip on flange yet boasts a fatigue strength 1.5 times that of the slip on design

- Employs both a backside hub weld and an internal shoulder weld for increased strength

- Socket weld flanges delivers a lower risk of leakage than threaded flanges

- Socket weld pipes do not have to be beveled for weld preparation

- Butt-welded joints are easily fitted and no special machining

Socket Weld Flange Disadvantages

- The expansion gap and internal crevices left in socket welded systems can promote crevice corrosion.

- Socket weld flanges have two welds which makes them stronger yet more labor intensive to install. Due to the increased welding, it has become the practice to weld only at the hub of the flange, which is not recommended.

Installation Tips

The socket weld pipe fittings should allow for expansion gap of 1/16 inch (1.6 mm) between pipe and the shoulder of the socket.