Ultra-strength combined with extreme temperature capabilities

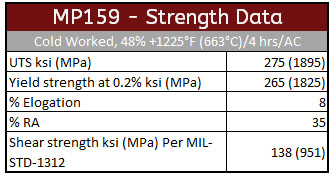

- Extreme high strength properties up to 275 ksi ultimate tensile.

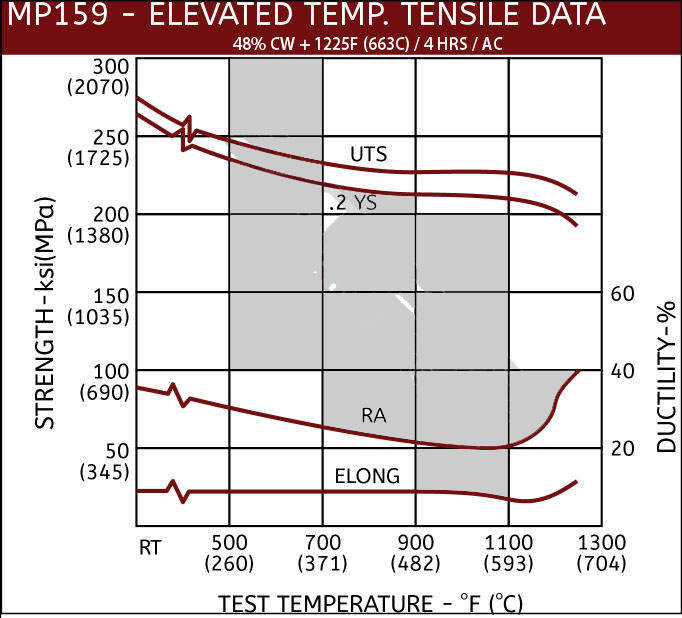

- Maintains superior strength to 1100°F.

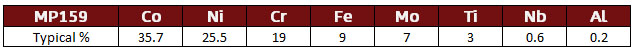

- MP159 chemisty and specification

- Datasheet for MP159

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Fasteners made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 fasteners offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159, can be used beyond 1100°F in short term situations.

Key Benefits

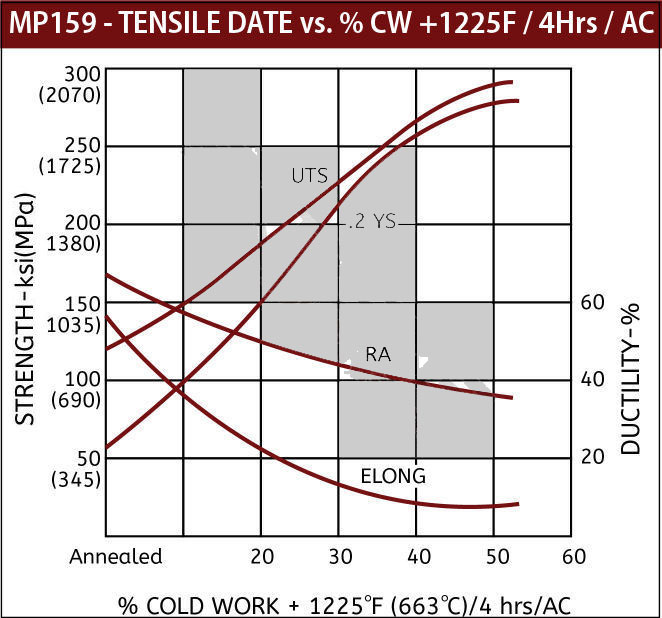

- High ultimate tensile strength of 275 ksi and yield strength of 265 ksi (Cold Worked and Age Hardened) combined with excellent ductility and toughness

- Similar corrosion resistance compared to MP35N which is usable in mineral acids, hydrogen sulfide, seawater and salt spray environments.

- Excellent fatigue resistance and creep strength at elevated temperatures

- Excellent resistance to crevice corrosion, stress corrosion cracking and hydrogen embrittlement

Applications

- The aerospace industry relies on MP159 fasteners for its most advanced gas turbine and jet engines, rocket boosters and jet propulsion systems.

- Power generation and chemical processing utilize MP159 bolts for applications that demand high strength at extreme temperatures.

Resources: MP159 Torque Spec

MP159 Fastener Types: Bolts, Nuts, Screws, Studs, Threaded Rod, Washers

MP159 Chemistry and Specifications

MP159N Specifications: UNS R30159

MP159 High Strength Data