Corrosion Resistant Gaskets: From sea water to strong acids

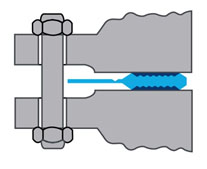

Our Revoseal corrosion resistant gaskets provide the lowest leak rate gaskets available to industry while being able to survive even the harshest marine, chemical and acid environments. Our semi-metallic design is offered in a variety of corrosion resistant alloys and soft seals (PTFE or graphite). Therefore we have the ability to tailor a gasket solution that is specific for your application's challenging needs.

| JG/JP Gasket |

|

Parameters

|

Applications

|

Advantages

|

Corrosion is one of the most common causes of gasket failure. From salt water applications to hot concentrated acids, Special Fasteners China. & Fastener offers the most corrosion resistant gaskets to protect against even the harshest environments. To protect your applications we offer gaskets in the following corrosion resistant materials and alloys:

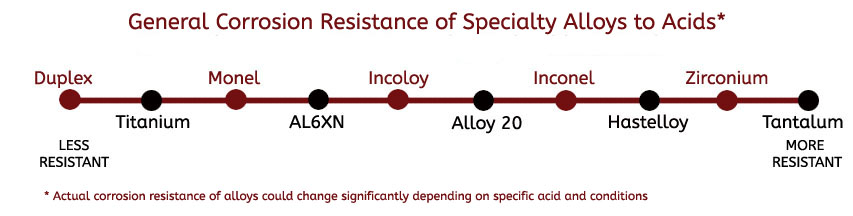

- Inconel 600, 601 & 625: The go to material of high temperature applications up to 1830°F / 1000°C. The high alloy content of Inconel gaskets enable it to withstand a wide variety of severe corrosive environments - both acidic and oxidizing chemicals. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel gaskets.

- Incoloy 800 & 825: Good temperature stability up to 1400°F / 760°C. Similar to Inconel but restricted to lower temperature use, Incoloy offers excellent resistance to seawater, brine, sour gas and high chloride environments at high temperatures. Incoloy gaskets also provide resistances to oxidation, carburization and creep. It is often used in the oil & gas industry.

- Hastelloy C276 & C22: Great for harsh corrosive media. One of the most versatile alloys for corrosion resistance, Hastelloy helps protect from a wide variety of corrosive environments - exceeding both Inconel and Monel in performance. Hastelloy gaskets offer resistance to sulfuric, hydrochloric, phosphoric, formic and acetic acids, chlorides, wet chloride gas, solvents, and acetic anhydride to name a few.

- Duplex & Super Duplex: Good for moderate acid environments. Characterized by their high yield strength, Duplex gaskets offer improved corrosion protection compared to 300 series stainless, especially in terms of localized corrosion such as crevice and pitting, as well as stress corrosion cracking. They work well in salt water and choride environment.

- Nickel 200: Excellent for caustic and select corrosive conditions. Made from commercially pure nickel, Nickel 200 gaskets provide excellent resistance to caustic alkali solutions such as caustic soda (NaOH).

- Titanium: Excellent for sea-water protection. Offering suuperior corrosion resistance to seawater, Titankum is also known for lightweight strength. They are widely used in chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper for their chloride and salt water resistance. Resistant to both rapid and stagnant seawater, titanium gaskets have proven resistance in decades of polluted seawater and are usable to up to a mile deep in the ocean.

- Tantalum: Only for the most severe acid environments. Known for its unmatched corrosion resistance and chemical inertness, Tantalum gasket are as corrosion resistant as glass, but with the mechanical properties of a metal. They are practically inert to many of the most corrosive environments. Tantalum gaskets are excellent for high concentration hydrochloric and sulfuric acid.

Corrosion Resources

- Nickel Alloy Corrosion Chart

- Hydrochloric Acid Iso-Corrosion ChartHydrochloric Acid Iso-Corrosion Chart

- Sulfuric Acid Iso-Corrosion Chart

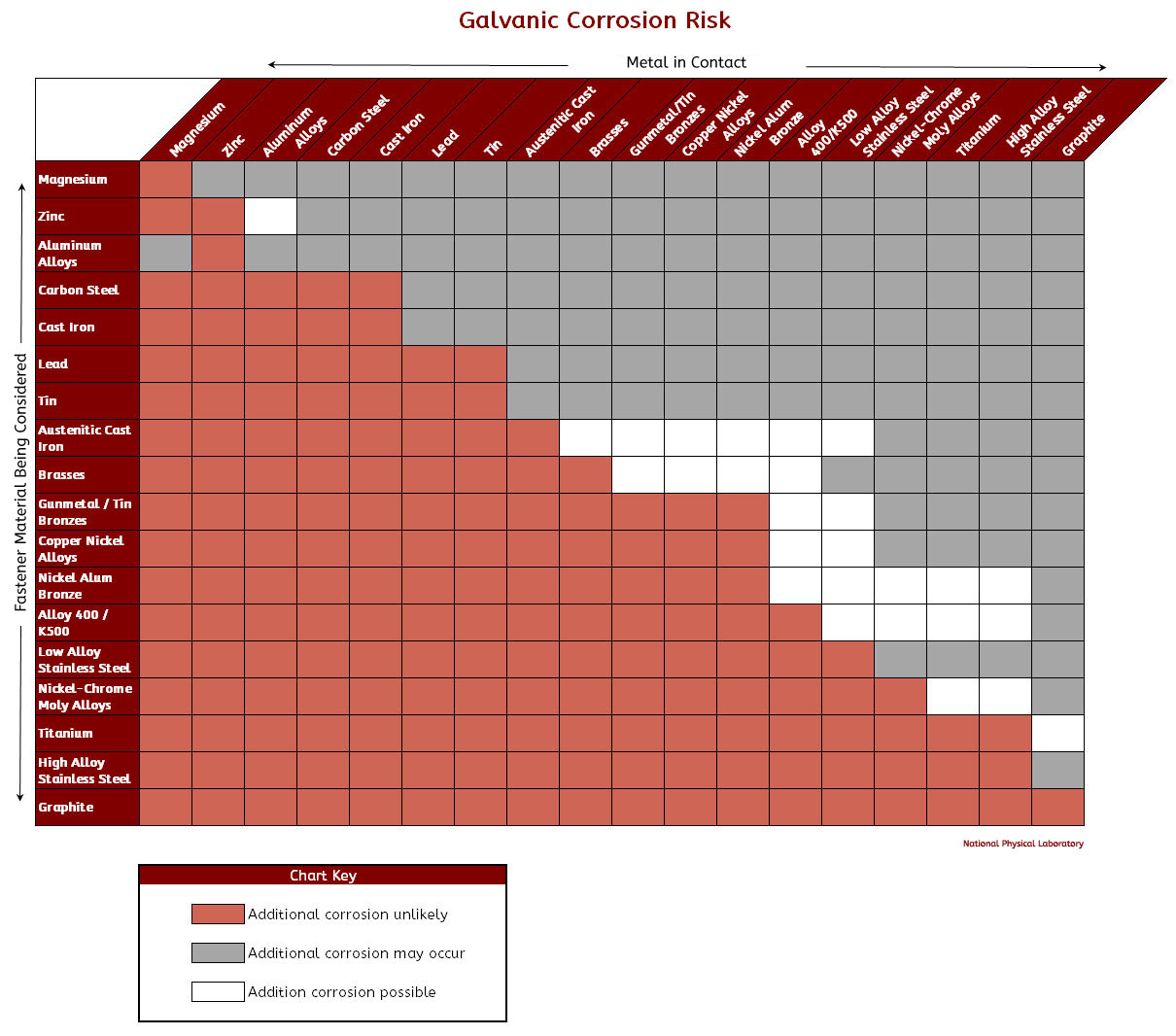

- Galvanic Corrosion Graph

Corrosion Resistance Comparison of High Performance Nickel Alloys

Tantalum, Zirconium & Hastelloy / HCl Iso-Corrosion Curves

Tantalum, Zirconium & Hastelloy / H2SO4 Iso-Corrosion Curves