Iso-Corrosion Curves

There are few environments more corrosive than hydrochloric acid. For this, only the toughest specialty metal fasteners will provide protection. This chart outlines the top performers in hydrochloric acid. In terms of HCl, the most resistant fasteners available are tantalum. Zirconium fasteners are second best, exhibiting a corrosion rate of less than 5mpy at all concentrations and temperatures of HCl below the boiling point. Though Zirconium provides excellent resistance, even small amounts of oxidizing media such as ferric or cupric chlorides will greatly decrease its corrosion resistance.

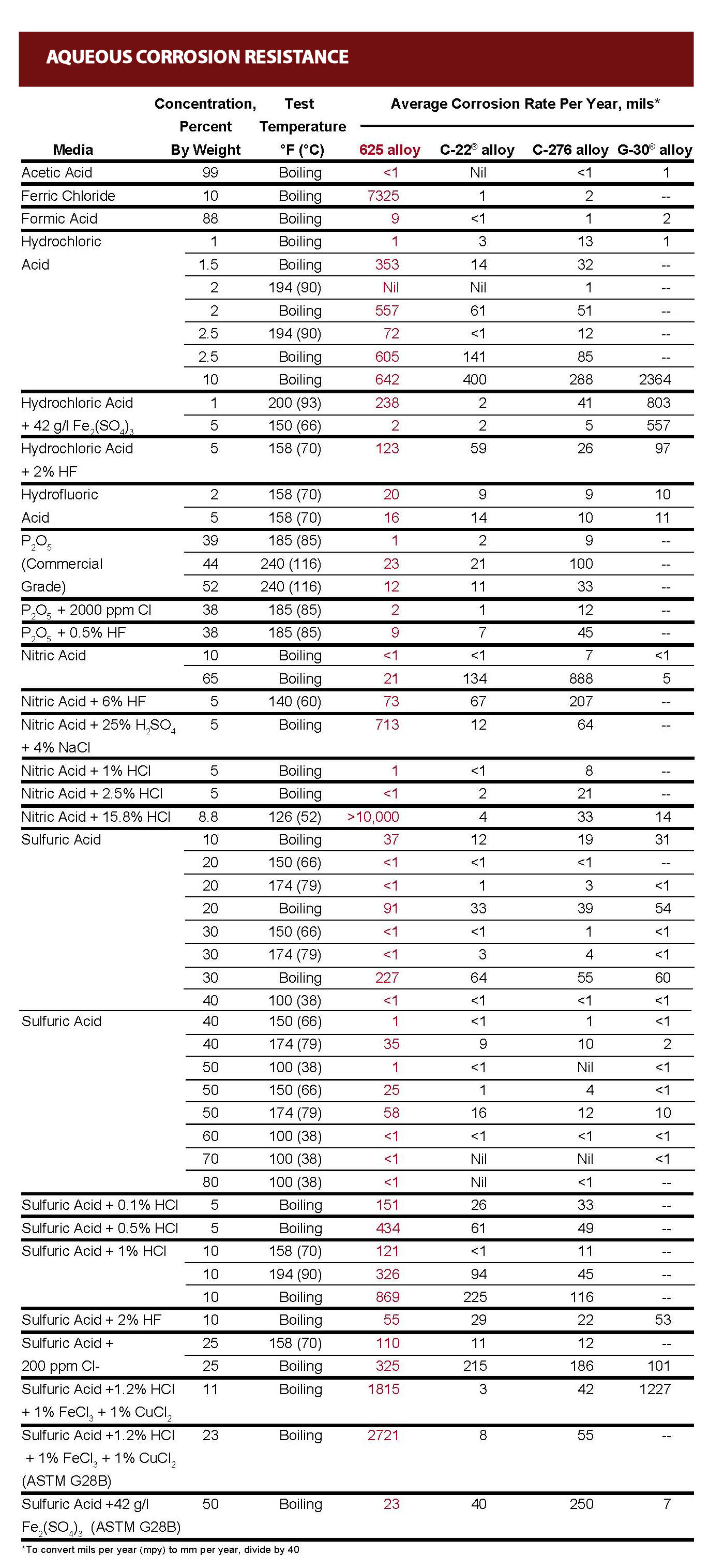

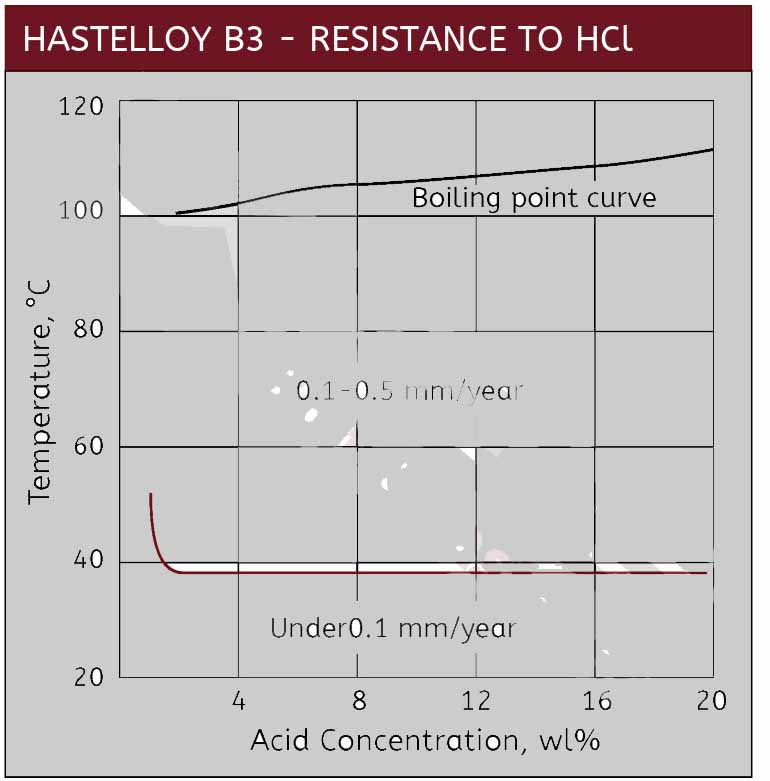

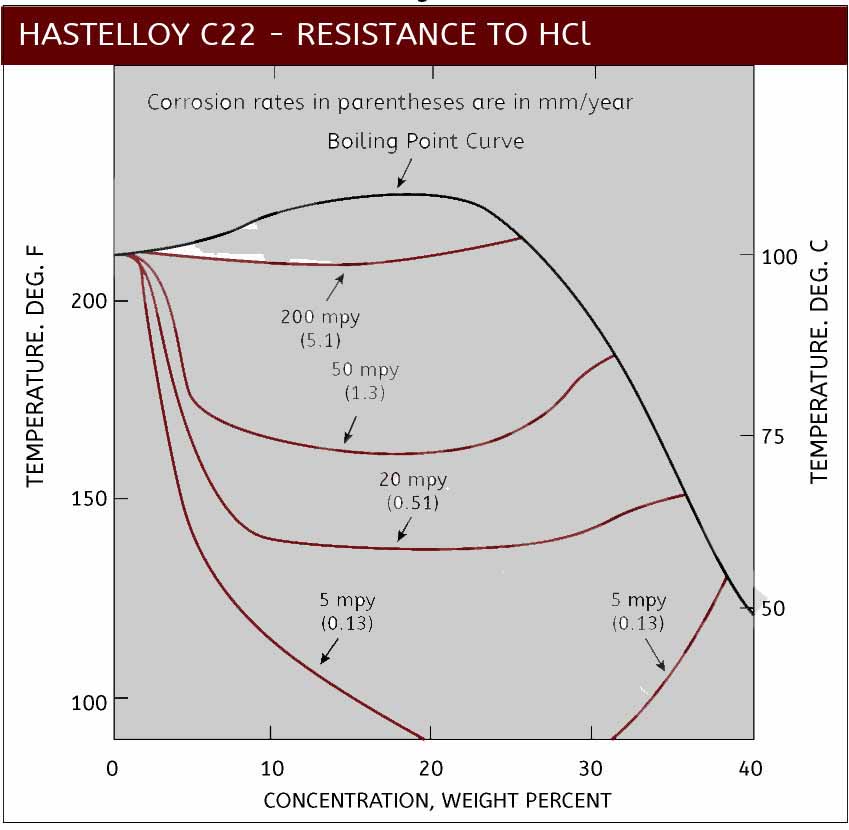

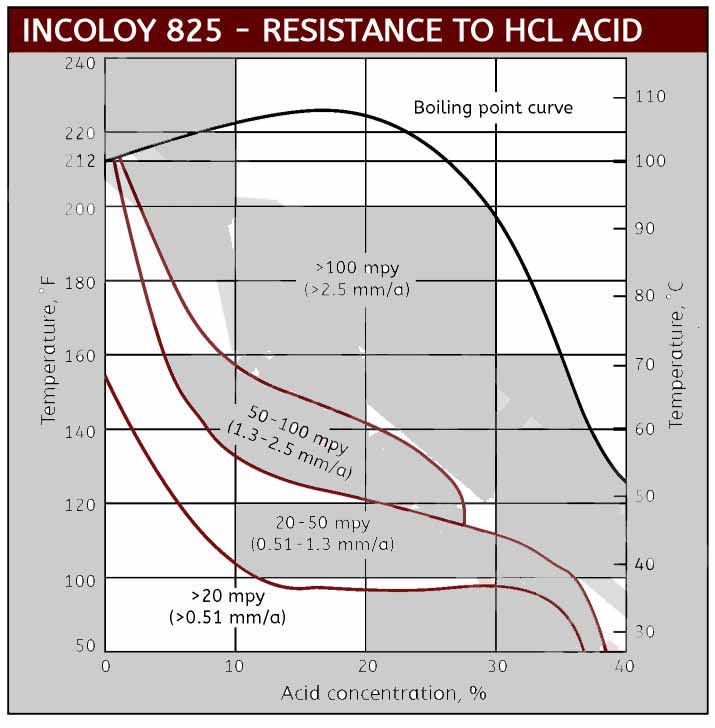

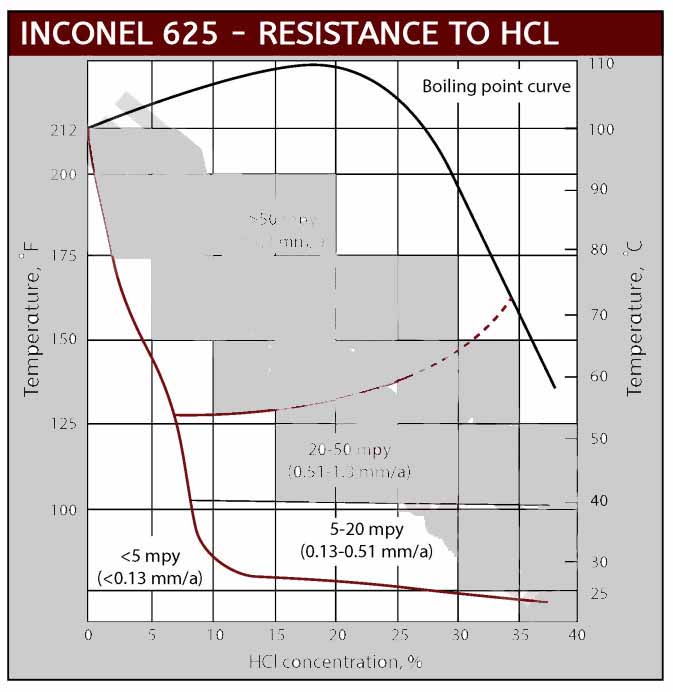

Next in line for hydrochloric acid performance are the high performance nickel alloy fasteners. The Hastelloy family of alloys are very well suitedto handle HCl at various temperatures and concentrations, yet some grades perform better than others in HCl. First Hastelloy B3 fasteners provide excellent resistance to hydrochloric acid at all concentrations and temperatures up to the 40°C, but like zirconium, experiences corrosion failure in the presence of oxidizers. In contrast, Hastelloy C22 screws is slightly less corrosion resistant thanHastelloy B3 fasteners, but are excellent in strong oxidizing environments and can perform well in the presence of ferric chlorides, cupric chlorides and nitric acid. For slightly more moderate hydrochloric acid environments, Inconel alloys are an excellent choice. Below is a chart comparing Hastelloy C22, Hastelloy C276 and Inconel 625 on hydrochloric acid, as well as other acids.

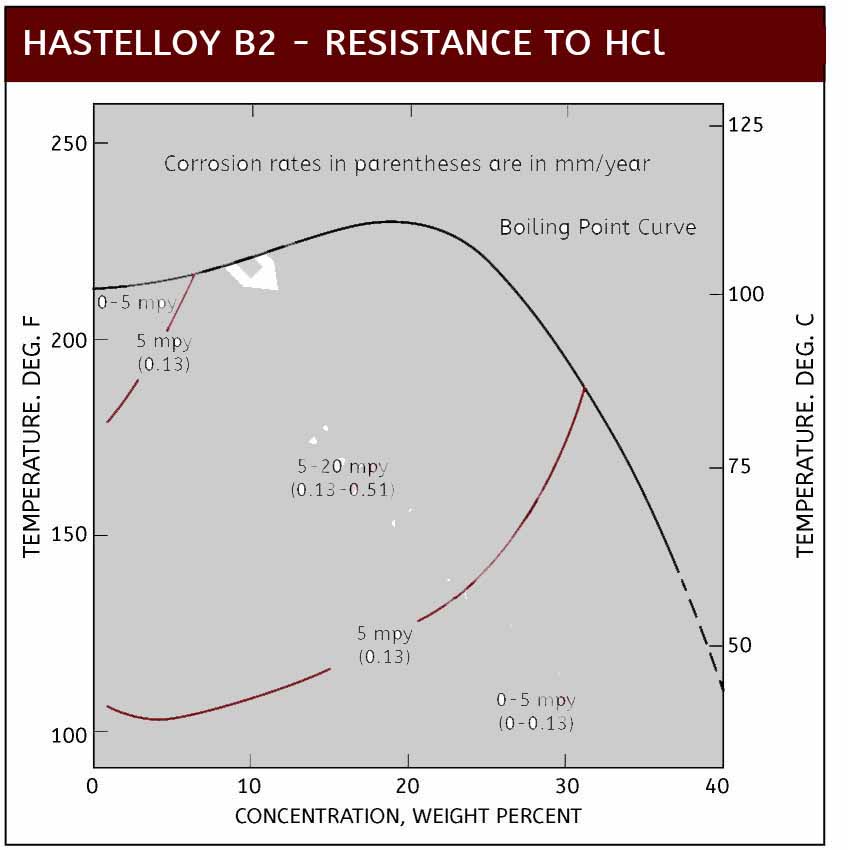

Hastelloy B2 Hydrochloric Acid Corrosion Performance

Hastelloy B3 Hydrochloric Acid Corrosion Performance

Hastelloy C22 Hydrochloric Acid Corrosion Performance

Hastelloy C276 Hydrochloric Acid Corrosion Performance

Incoloy 825 Hydrochloric Acid Corrosion Performance

Inconel 625 Hydrochloric Acid Corrosion Performance

Tantalum Hydrochloric Acid Corrosion Performance