A high performance nickel alloy for severe corrosion environments

A high performance nickel alloy for severe corrosion environments

- Excellent corrosion resistance to reducing and oxidizing environments

- Well suited for hydrochloric and sulfuric acid environments

- Strong resistance to stress corrosion cracking

- Excellent mechanical properties at elevated temperatures

- Weld studs available in Hastelloy C276

- Features & benefits of Hastelloy weld studs

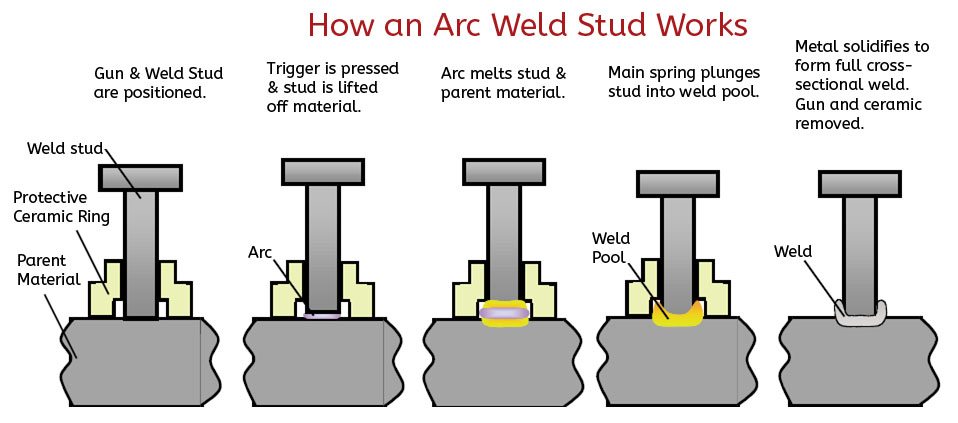

- How a Hastelloy arc weld stud works

- Hastelloy C276 datasheet

Hastelloy C276 weld studs are available in a variety of fastener styles for manual (MIG, TIG) arc and capacitor discharge welding methods. Delivering excellent corrosion resistance, Hastelloy C276 weld studs provide a secure, cross-sectional weld in single-sided access situations for a wide variety of extreme environments. Hastelloy weld studs are especially known for their exceptional resistance to both sulfuric acid and hydrochloric acid.

Because Hastelloy weld studs resist some of the most severe media, they are often utilized in chemical processing applications where acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorites, chlorine solutions and phosphoric acid are used. For chemical processing applications, Hastelloy C276 is the most common grade and one of the most corrosion resistant nickel alloys - exceeding that of most other nickel alloy grades like Inconel or Monel.

Resources: Hastelloy Torque Spec

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Torx Screws

Hastelloy Weld Stud Features & Benefits

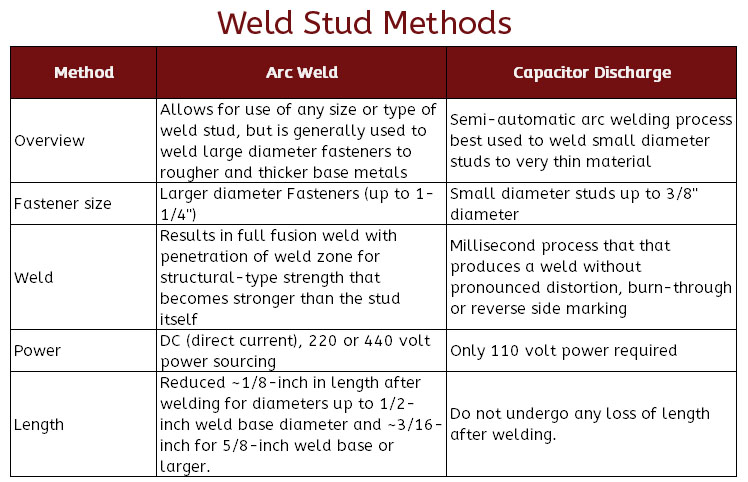

Hastelloy C276 weld studs are an ideal way to securely attached fasteners in extreme applications where reaching both sides of a structure is impossible or undesired. These weld studs can be attached by a variety of welding techniques, such as MIG or TIG welding or they can be attached by automated welding guns using Arc or Capacitor Discharge (CD) technologies.

Arc and Capacitive Discharge (CD) Weld Stud Benefits

Arc and Capacitive Discharge (CD) Weld Stud Benefits

- Security: Unlike the peripheral weld used on a common bolt, the weld used to secure a weld stud fastener is a full cross sectional weld, so the full face of the fastener is welded in place for a strong, secure hold. And since there are no drilled holes – which weakens the structural integrity of the application – the attachment is even stronger.

- Speed: Installing a Hastelloy weld stud is a fast and simple process with a most fasteners taking less than 1 second to weld in place. Plus there is no secondary work such as drilling, polishing or grinding.

- Simplicity: Weld studs require almost no special skills and minimal training and equipment is needed for installation. In addition, the equipment is also portable.

- Variety: Hastelloy weld studs are available in a wide variety of fastener styles including (but not limited to) fully threaded, partially threaded, full base, reduced base, long, tapped base, and shoulder thread to name a few.

Hastelloy C276 Weld Stud Chemistry & Specifications

HASTELLOY(R) C-276

C276 alloy, UNS N10276, is the most widely used and versatile, corrosion resistant alloy. Very good resistance to reducing, and mildly oxidizing corrosives. Excellent stress corrosion cracking resistance with very good resistance to localized attack. For more indepth material information download our Hastelloy C276 datasheet.

Hastelloy C276 Specifications: N10276, ASTM B574, ASME SB574, Werkstoff 2.4819, ASTM G28-A/B, EN 10204-3.1, ASME B18.2.2, ASTM B619, ASME SB619, ASTM B366, ASME SB366, WPHC276, ASME B16.11, ASTM B564/ASME SB564, COLD DRAWN, HOT FINISHED, ASTM B575, ASME SB575, COLD ROLLED, HOT ROLLED, ASME B16.9, ASME B16.5, ASTM B462, ASME SB462

Mechanical Properties of Hastelloy

|

|

Hastelloy Corrosion Data