Economic choice for light-weight strength

Lightweight at about 1/3 the weight of steel

- Good fatigue resistance and toughness

- Aluminum 7075 strength chart

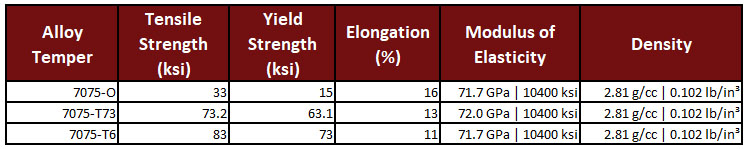

- Mechanical properties of Aluminum 7075

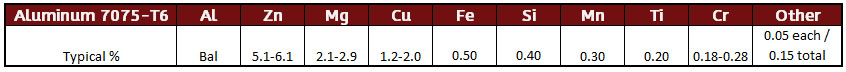

- Chemistry and specifications of Aluminum 7075

- Availability and lead times

- Aluminum 7075 fastener styles

- Aluminum 7075 datasheet

Aluminum 7075 fasteners are most commonly used for their combination of high strength and low weight. Alloyed primarily with zinc, they exhibit strength that is comparable to many grades of steel at a fraction of the density. Aluminum 7075 can be tempered to several different conditions (including 7075-T6) which offers different levels of strength. Commonly used for high-stress aircraft parts, Aluminum 7075 bolts offer good fatigue resistance and toughness.

Compared to aluminum alloy 2024, 7075 bolts are typically used in applications where high strength and low weight are critical, whereas 2024 is more suited for cyclic fatigue. When weighing their attributes against 6061 which is structural aluminum, 6061 offers better corrosion resistance and machinability, but does not have the same high strength as aluminum 7075 fasteners.

Key Attributes

o High strength compared to other aluminum alloys

o Lightness: Aluminum weighs about one third of steel

o Good fatigue strength

o Good ductility and toughness

o Economic strength-to-weigh ratio

o Low density

o Non-magnetic

o Usable to ~752F / 400C

Aluminum 7075 Fastener Availability

Availability

Special Fasteners China. & Fasteners offers many types of Aluminum 7075 fasteners including screws, nuts, washers and threaded products. We typicially have a minimum order quantity of 20 pieces for most fasteners. Standard lead time for aluminum fasteners is about 3-4 weeks, depending on the complexity and quantity.

- Diameter sizes: Standard #00 – 4” in diameter / Metric M1.2 – M48

- Threads: UNC, UNF, UNJ, UNR, Rolled,and Cut

- Custom to print available.

- ASTM, ASME, and Domestic available

Expediting Options

Many applications cannot wait and require a faster than normal lead time. We understand and are here to help. If you need expedited shipping, please let us know when submitting a quote so that we can do our best to accommodate your specific needs.

Aluminum 7075 Fastener Styles

| Aluminum 7075 Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

| ||

| Aluminum 7075 Bolts | Hex Head Bolts, Shoulder Bolts | o DIN 931 o DIN 933 o ISO 4014 o ISO 4017 o ISO 7370 | ||

| Aluminum 7075 Nuts | Hex Nuts, Lock Nuts | o DIN 439 / ISO 4035 o DIN 934 / ISO 4032 o DIN 985 / ISO 7040 o DIN 986 o DIN 980 / ISO 7042 / ISO 19513 o DIN 6923 / ISO 4161 | ||

| Aluminum 7075 Threaded Products | Studs, Threaded Rods | o DIN 975 o DIN 976 | ||

| Aluminum 7075 Washers | Flat Washers, Lock Washers | o DIN 125 / ISO 7089 / ISO 7090 o DIN 126 / ISO 7091 o DIN 127 / ISO 7090 o DIN 9021 / ISO 7093 |

Aluminum 7075 Chemistry & Specifications

Aluminum 7075 Specifications: UNS A97075, QQ-A-200/11, AMS-QQ-A-200/11, ASTM-B211, AMS 4154

Aluminum 7075 Mechanical Properties

Aluminum 7075 Strength Chart

Aluminum 7075 Screws

| 12 point screws are most often used for applications that need a higher torque bolt than a socket head cap screw. We offer 12 points in 1/4" diameter or larger. The only drawback is Aluminum 7075 12 point screws are less economical and require a high minimum quantity due to the complexity of production. | o IFI-115 o MIL SPEC o DIN 34822 o DIN 34821 | |

| For a wide-clamping area and low-profile fastener, Aluminum 7075 button head cap screws are an ideal choice. Button head screws are also used when you must fasten a material that is too thin to counter bore. | o ASME B18.3 o ASME 18.3.4M o DIN 7380 / ISO 7380 | |

| Flat head screws have a standard 82° countersink angle and typically feature a slotted or socket driver. Aluminum 7075 flat heads are also available with angles ranging from 60° -120° upon request. Phillips, torx and tamperproof drivers are also available depending on size, quantity and material. | o ASME B18.3 o ASME B18.3.6 o DIN 963 / ISO 2009 o DIN 965 / ISO 7046 o DIN 7991 / ISO 10642 | |

| Aluminum 7075 hex head cap screws are the most common fastener. They have an added washer face providing tighter dimensional tolerances over a hex bolt which lacks this element. Aluminum 7075 hex head cap screws provide high clamping force and easy access. | o ASME B18.6.3 o DIN 931 / ISO 4014 o DIN 933 / ISO 4017 o DIN 961 / ISO 8676 | |

| Aluminum 7075 pan head screws have a rounded head and are ideally used for small diameter and low torque applications. They typically feature a slotted driver. | o ASME B18.6.3 o DIN 7985 o DIN 921 o DIN 85 / ISO 1580 o DIN 84 / ISO 1207 (cheese head) o DIN 966 / ISO 7047 (raised counter sunk) | |

Security Screws Security Screws | When applications demand unwanted removal or tampering, Aluminum 7075 security screws provide protection because they cannot be unfastened using an common driver. Tamper-proof screws are produced in a wide variety of head styles, as well as custom per print. | |

| Aluminum 7075 set screws have no head. This fastener has a slotted or socket driver on one end and a unique point on the other. Set screws are available with cup, cone, flat, dog and half-dog points. | o ASME B18.3 o DIN 913 / ISO 4026 o DIN 914 / ISO 4027 o DIN 915 / ISO 4028 o DIN 916 / ISO 4029 | |

| Aluminum 7075 socket head cap screws are ideal for low clearance applications that require a safe and secure fastener. | o ASME B18.3 o DIN 912 / ISO 4762 o DIN 7984 | |

| Aluminum 7075 vented screws provide a way to out-gas application contaminents through a vertical hole drilled from the screw head through the threaded shaft. Vented screws are ideal for vacuums / high vacuums. Nimonic vented screws are available a variety of head styles. |

Aluminum 7075 Bolts

| Similar to hex head cap screws but without the washer face, Aluminum 7075 hex bolts are a good choice when high clamping force is needed for easily accessible applications. | o ASME B18.2.1 o DIN 931 / ISO 4014 o DIN 933 / ISO 4017 | |

| Aluminum shoulder bolts have a head, smooth shoulder section (for rotating parts) and botttom threaded portion. Shoulder bolts typically have a socket driver. | o ASME o DIN 7379 / ISO 7379 o ISO 7370 |

Aluminum 7075 Nuts

| We offer Aluminum 7075 nuts in several styles including: finished hex nuts, jam nuts and heavy hex nuts. | o ASME B18.16.3 o ASME B18.2.2 o DIN 439 / ISO 4035 o DIN 934 / ISO 4032 o DIN 986 | |

| Aluminum 7075 lock nuts are offered as all-metal and polymer/nylon insert styles. All-metal lock nuts such as stover and flexloc are ideal for high temperatures and even load distribution. Nylon (polymer) insert lock nuts are more economic but can only be used when temperatures are under 350°F. | o ASME B18.16.3M o DIN 980 / ISO 7042 / ISO 19513 o DIN 6923 / ISO 4161 o DIN 985 / ISO 10511 / ISO 7040 |

Aluminum 7075 Studs & Threaded Rod

| Aluminum 7075 studs are threaded rods less than one foot in length. They can be fully or partially threaded (such as double ended studs) and are available in any custom length. | o ASME B18.31.2 o DIN 976 | |

| Aluminum 7075 threaded rods are available in any custom length greater than 1 foot. The minimum order quantity for threaded rod is 6 feet of total length (for example 2, 3-foot pieces) and our maximum shipment length is 6 feet. | o ASME B1.1 o DIN 975 |

Aluminum 7075 Washers

| Special Fasteners China. & Fastener offers Aluminum 7075 washers in several specifications including SAE, USS, DIN, oversized, and custom per print. | o ASME 18.21.1 o SAE / USS o DIN 125 / ISO 7089 / ISO 7090 o DIN 126 / ISO 7091 | |

| Aluminum 7075 lock washers are available in the split lock washer style. | o ASME B18.21.1 o DIN 127 / ISO 7090 o DIN 6796 / ISO 10690 |