Inconel 718/Alloy 718 (2.4668) Key Benefits:

- Excellent corrosion resistance at elevated temperatures

- Excellent creep and stress rupture strength, at elevated temperatures to 1300°F (700°C)

- High strength material

- Heat treaments offering tensile strength range:185-220ksi

- Download our Inconel 718 datasheet

An age hardened nickel-chromium-based superalloy, Inconel(R) 718 (2.4668) fasteners and flanges are ideal for extreme environments that require oxidation and corrosion resistant fasteners, even when subjected to pressure and heat. Twice as strong as Inconel 625 fasteners, 718 fasteners are renowned for its high yield strength up to 1300°F. Often selected by industry for their high temperature strength capabilities, Inconel 718 fasteners and flanges also deliver strength and ductility at cryogenic temperatures.

Also known as alloy 718, Inconel 718 fasteners are a precipitation hardened (also called age hardened) form of Inconel 625. This heating and quenching process is used to change the alloy’s atomic structure, making it stronger by locking the metal's grain structure in place. Additional strength could be gained by cold working.

Corrosion Resistance

Similar to its 625 counterpart, Inconel 718 bolts offer excellent resistance due to their nickel-chromium content, even combating chloride-ion stress-corrosion cracking. The nickel in alloy 718 helps provide resistance to many inorganic and organic compounds throughout wide ranges of acidity and alkalinity, with the exception of strongly oxidizing compounds. It's chromium content enables it to withstand sulfur compounds and mild oxidizing media, while molybdenum helps prevent pitting. Key corrosion resistance attributes of Inconel 718 include:

- Highly resistant to chloride and sulfide stress corrosion cracking.

- Excellent resistance to H2S, CO2, chloride, and sour gas environments.

- Resistant to aqueous corrosion.

- Provides protection in oil & gas drilling environements at high temperatures.

Thread Creation

Threads can also be rolled or cut in the annealled condition. Once aged hardnend, additional work via rolling or cutting becomes very difficult but can done for certain applications that require the highest strengths possible.

Welding

Known for having outstanding weldibility, Inconel 718 fastners and flanges can be welded in either the annealled or aged condition. This is partiuclarly useful for applications utilizing weld studs. Due to its age hardening process, Inconel 718 fasteners can be welded without hardening or cracking. Keep in mind that when welding in the aged conition will cause the formation of a softened heat-affected zone.

Overview of Chemistry

Inconel 718 fasteners and flanges are a nickel-chromium alloy. They contain significant amount of iron, columbium, and molybdenum, along with lesser amounts of aluminum and titanium.

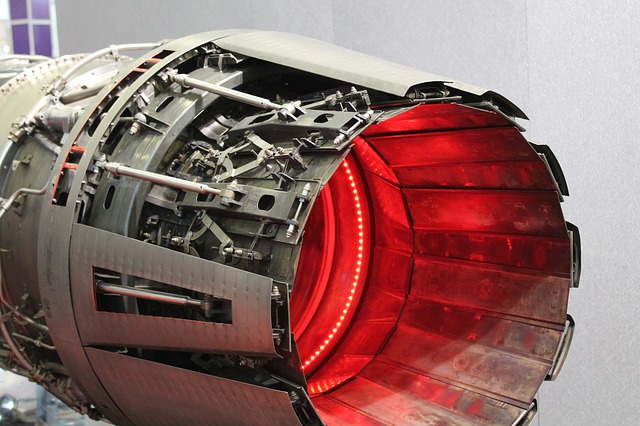

Inconel 718 Fasteners & Flanges in Action: Extreme Applications

- Natural gas processing where contaminants such as H2S and CO2 are present

- Aerospace also uses Inconel 718 fasteners for liquid oxygen turbo-pumps, gas turbine engines and airframe parts

- Down-hole oil shafts and wellhead parts

- Chemical processing

- High temperature applications like steam generators and nuclear pressurized water reactors

- Cryogenic tanks

Inconel 718 Grades, Chemistry and Specifications

Inconel 718 (alloy 718), UNS N07718, is the most common grade of the hardenable Inconel nickel alloys. This precipitation-hardened nickel-chromium alloy combines outstanding corrosion resistance and high strength at elevated temperatures. The alloy is a about 2x as strong as Inconel 625 having excellent creep-rupture strength at temperatures to 1300°F (700°C) and can withstand temperatures up to 1800°F (982°C). Inconel 718 is often used in gas turbines, rocket motors, spacecraft, nuclear reactors, pumps, and tooling.

Inconel 718 Specifications: AMS 5596, AMS 5662, AMS 5663, AMS 5962, AMS 5832, ASME Case 2222-1, ASME SFA 5.14, ASTM B 637, ASTM B 670, EN 2.4668, GE B50TF14, GE B50TF15, UNS N07718, Werkstoff 2.4668

Mechanical Data

|  |

Inconel 718 Heat Treatment Strengths

Inconel Corrosion Data