Inconel 625/Alloy 625 (2.4856) Key Benefits:

- Very good corrosion resistance at elevated temperatures

- High temperature stability up to 2200°F (982°C)

- High strength material with excellent toughness at elevated temperatures

- Inconel 625 datasheet

Developed in the 1960’s as a material for steam-lined piping, Inconel(R) 625 (2.4856) screws deliver high strength, even at extreme high temperatures from freezing cryogenics to 1800°F. Also known as alloy 625, Inconel 625 screws are renowned for their amazing ability to retain their strength and resist heat, both in and out of corrosive environments. The presence of nickel and chromium make Inconel 625 screws corrosion, oxidation and carburization resistant. The molybdenum also helps to deliver excellent fatigue strength and resistance to stress, pitting and crevice corrosion cracking even when exposed to chloride ions.

Corrosion Resistance

Due to ability of Inconel 625 screws to prevent, stress, crevice and pitting corrosion, it is utilized in a diversity of corrosive environments. In mild applications such as atmosphere, fresh or salt water, neutral salts and alkaline media is is almost completely resistant. In more severe situations the nickel and chromium content provides resistance to oxidizing chemicals. Inconel 625 screws are also resistant to nonoxidizing environments. Better understand Inconel 625's corrosion resistance to:

Welding

Inconel 625 screws are readily weldable with conventional welding processes and this is particularly useful for Inconel 625 weld studs. This alloy is often chosen for its weldibility compared to other highly alloyed nickel-base alloys. Even in welded condition, alloy 625 is also resistant to intergranular corrosion. In addition, postweld heat treatment of the weld is not necessary to maintain corrosion resistance.

Overview of Chemistry

Inconel 625 screws are a nickel alloy whose strength is derived from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix. This provides alloy 625 strength without the need for precipitation hardening. The high molybdenum content of Inconel 625 makes these screws very resistant to pitting and crevice corrosion, while the niobium acts to stabilize the it against sensitization during welding, subsequently preventing cracking. The core element of nickel provides 625 the ability to prevent chloride ion stress corrosion cracking.

Inconel 625 Screws in Action: Extreme Applications

- Resistant to chloride ions, pitting and crevice corrosion; high corrosion-fatigue strength, high tensile strength make Inconel 625 screws perfect for marine use.

- Nuclear power plants use Inconel 625 screws for reactor core and control rod screws.

- Heat shields, furnaces and gas turbine engines.

- Wide range of temperature and pressure resistance make 625 screws a key component of chemical processing plants.

- It is an ASME approved material of construction under the Boiler and Pressure Vessel Code

Inconel 625 Grades, Chemistry and Specifications

Inconel 625 (alloy 625), UNS N06625, is the workhorse of the Inconel family and is one of the most common grades. This nickel alloy exhibits high creep-rupture strength and is oxidation resistant to 1800°F (982°C). Inconel 625 has excellent resistance to hot seawater, scrubber environments and reducing acids and this alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion.

Inconel 625 Specifications: AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3, UNS N06625, Werkstoff 2.4856

Mechanical Data

|  |

Inconel Corrosion Data

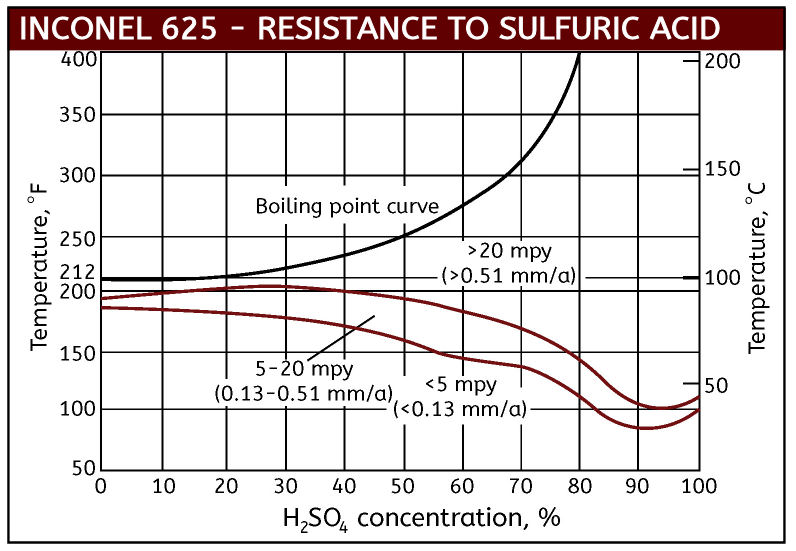

Inconel 625 Sulfuric Acid Iso-Corrosion Curve

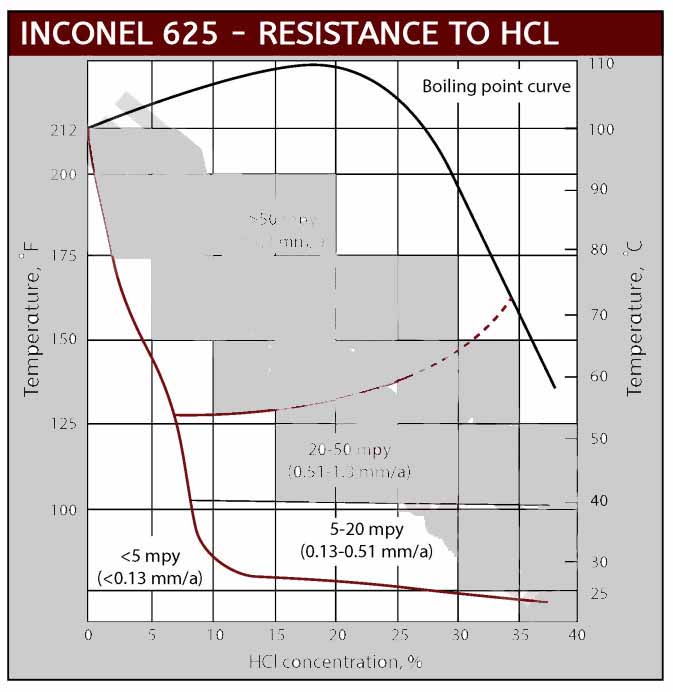

Inconel 625 Hydrochloric Acid Iso-Corrosion Curve

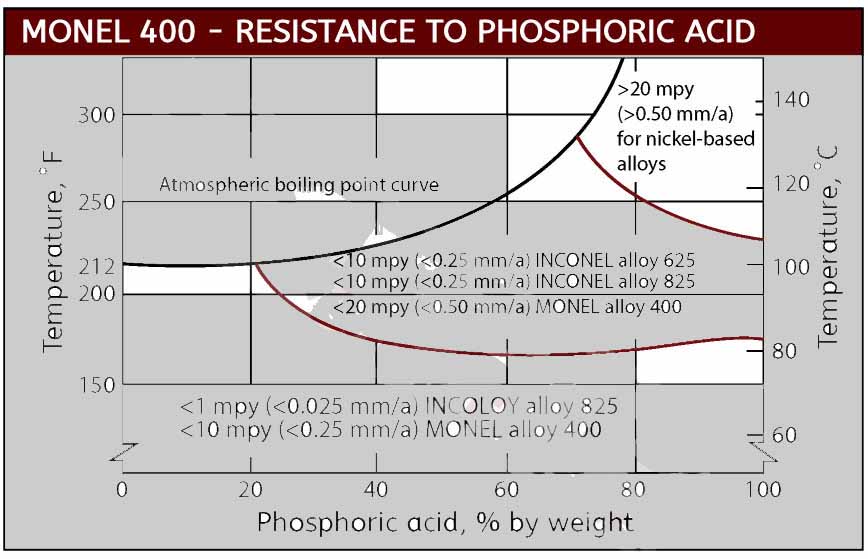

Inconel 625 Performance in Phosphoric Acid