An engineered high temperature resistant steel

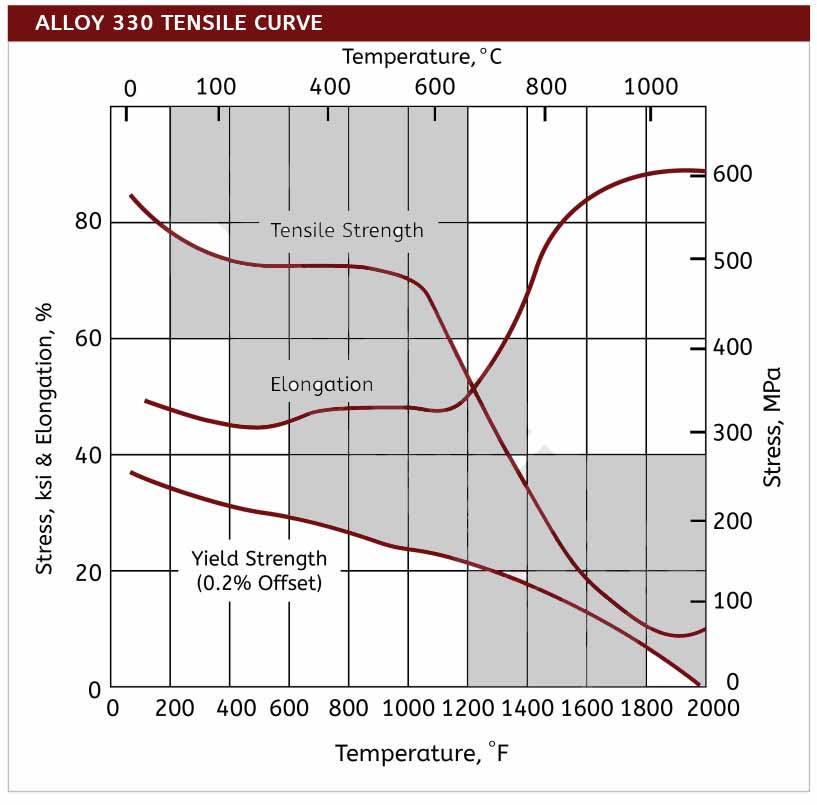

- Excellent high temperature stability and strength

- Very oxidation and carburization resistant to 2100°F

- Good resistance to thermal shock and quenching

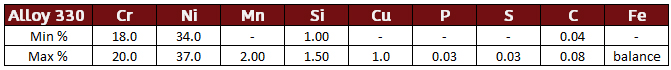

- Chemistry and specifications of alloy 330

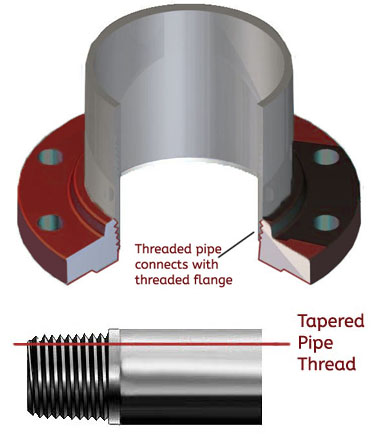

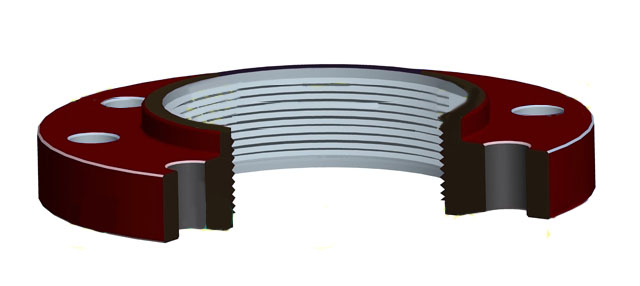

- Threaded flange features and benefits

- Alloy 330 Datasheet

Alloy 330 threaded flanges are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic nickel-chromium-iron-silicon alloy, 330 threaded flanges also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Benefits & Corrosion Resistance

- Resistance to thermal shock from repeated quenching

- High level of resistance to oxidation and carburization

- Ability to handle thermal cycling

- Provides resistance to scale formation up to about 2000°F

- Good resistance to nitrogen-containing atmospheres where the oxygen content is low

- High nickel content of 34-37% provides high resistance to chloride stress corrosion cracking and embrittlement

Applications for Alloy 330 Threaded Flanges

- Alloy 330 flanges are often used in furnaces, thermal processing and heat treating applications.

- Gas turbine components and boiler fixtures used in power generation often use Alloy 330 threaded flanges.

- Because of its resistance to nitrogen rich environments, alloy 330 flanges are used extensively for components handling cracked ammonia.

| Alloy 330 Properties | |

| Tensile Strength (ksi) | 80-85 |

| Yield Strength (ksi) | 30-43 |

| Elongation in 2” | 40-45 |

| Rockwell B Hardness | 70-85 |

| Density (lb/in3) | 0.292 |

| Specific Heat (Btu/lb/°F (32°-212°F) | 0.11 |

| Modulus of Elasticity Tension | 28.5 |

Resources: Alloy 330 Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

Alloy 330 Threaded Flange Features & Benefits

Alloy 330 threaded flanges have a tapered female thread to join the male threads of a pipe in order to create a tight seal. This type of flange is most ideal when post weld heat treatment is not possible in hazardous, flammable or explosive applications where welding is too dangerous. Alloy 330 threaded flanges are also convenient in pilot processes whose configuration is often changed.

Threaded Flange Advangtages

- The main benefit is that that threaded seal eliminates the need for welding.

- As they do not require welding they save time and money to install.

- Allow for connections to be made in dangerous, explosive applications where welding is not possible.

- Useful connection in materials that are difficult to create a successful and strong weld.

- Ideal for connecting small diameter pipes.

- Systems could be easily reconfigured.

Threaded Flange Disadvantages

- They are not suitable where high temperatures, frequent cyclic conditions or bending stresses are likely in applications.

Alloy 330 Chemistry and Specifications

Alloy 330 (UNS N08330) is best known for its extreme high temperature strength and stability. One of the most unique attributes of Alloy 330 is its ability to handle cyclic temperature changes from extreme high temperatures to cooling phases, as well as in oxidation-rich environements.

Alloy 330 Specifications: UNS N08330, AMS 5592, AMS 5716, ASME SB 511, ASME SB 536, ASTM B 511, ASTM B 512, ASTM B 535, ASTM B 536, ASTM B 546, ASTM B 710, ASTM B 739, EN 10095, Werkstoff 1.4886