Sealing from cryogenic to 1000°C we cover it all...

Whatever the temperature of your application, Special Fasteners China. & Fastener offers high temperature gaskets that are designed to seal endure the most challenging environments from cryogenic temperatures to red hot applications up to 1830°F / 1000°C.

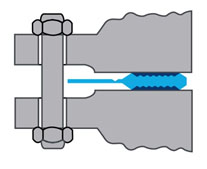

Specialty High Temperature Metal Gaskets

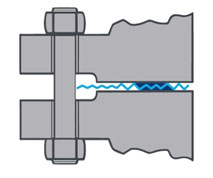

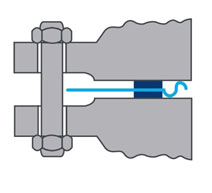

All of the Revoseal gaskets can operate at elevated temperatures as they are constructed from a stainless steel and graphite design that feature a metal-to-metal seal that protects and isolates the graphite from the process and air. As a result, the graphite will not coke or burn from the oxygen.

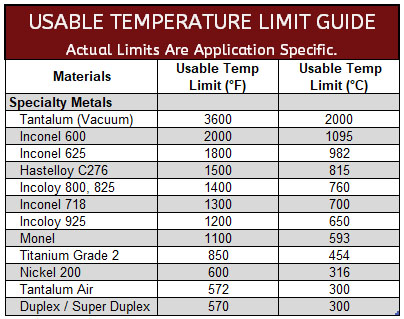

When temperatures go beyond 932°F / 500°C specialty alloys can be utilized in our JG / JP gaskets.

Our highest temperature gasket JG / JP, are available with specialty alloys like Inconel 625 or Incoloy. The combination specialty alloys, graphite and our unique metal-to-metal seal, will easily handle the hottest environments that could be found in applications such as vacuum furnaces, nuclear, chemicals and refractory metal processing.

| Revolution Gasket | Eco+ Gasket | JG/JP Gasket |

|  |  |

Parameters

| Parameters

| Parameters

|

Applications

| Applications

| Applications

|

Advantages

| Advantages

| Advantages

|

Specialty Material High Temperature Gaskets