An extremely strong precipitation hardened stainless steel

- Well suited for high strength applications

- Up to 4x stronger than 316 stainless steel

- Maintains its mechanical strength up to 600°F

- 17-4PH Chemistry & Specifications

- Lap joint flange features and benefits

- 17-4PH Datasheet

17-4 PH lap joint flanges are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH lap joint flanges yield strength is up over 4 times greater. When compared to Duplex 2205 lap joint flanges, the yield strength of 17-4 PH can be up to 2- 1/2 times greater.

17-4 lap joint flanges are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below).

Resources: 17-4PH Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, Werkstoff 1.4542, AISI 630, ASTM A564-630, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

This specification covers bars and shapes (such as fasteners) of age hardened stainless steels such as 17-4PH. It includes hot-finished or cold-finished fasteners that are produced by hot rolling, extruding, or forging. Grade 630 shall be furnished in the solution-annealed or or age-hardened condition.

Common 17-4 Lap Joint Flanges: Aged Conditions vs Tensile Strength

17-4PH Lap Joint Flange Features & Benefits

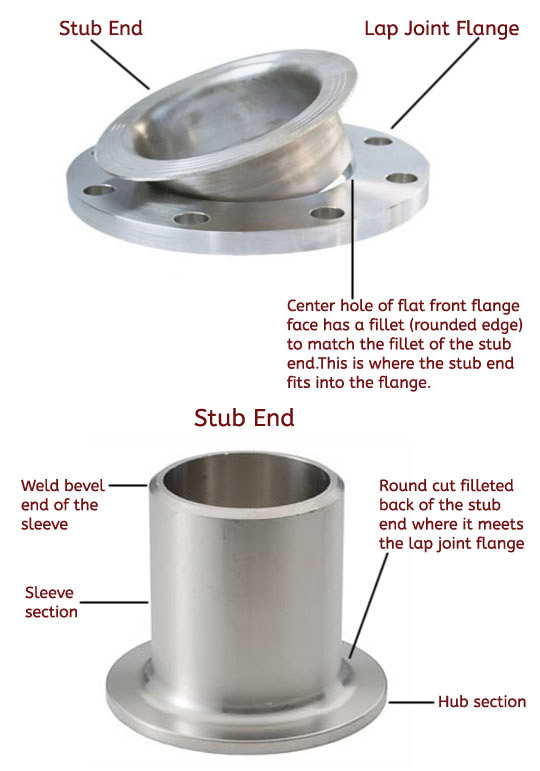

Lap joint flanges are unique in that they are made of two pieces, the flange itself and the stub end.

Flange

- The backside, has a slight shoulder that is square cut at the center or pipe hole

- The front side has a flat face with a filleted (rounded) center hole to match the filleted back face of the stub end. Here the stub end will wrap tightly around the center hole of the flange.

Stub End

- Shaped like a short piece of pipe with a weld bevel on one. This portion of the stub end is also called the sleeve.

- Narrow shoulder on the flange facing end called is the hub. The back face of the hub has a rounded transition (or inside fillet) that joins the hub to the sleeve

Benefits

- Economy

Because a lap joint flange has a two piece configuration, it offers a way to cut cost when piping systems requires - For high cost alloys the only "wetted" part is the stub end. In this situation, it is only required for the stub-end to be made of the higher cost corrosion-resistant material, where the flange itself can be the produced from lower cost steel.

- Ease of Work

By using lap joint flanges, work can be simplified in situations that require frequent and rapid disassemble and assembly during the operation of a plant. The ability to spin that backing flange compensates for misalignment of the bolt holes during assembly.