An extremely strong precipitation hardened stainless steel

- Well suited for high strength applications

- Up to 4x stronger than 316 stainless steel

- Maintains its mechanical strength up to 600°F

- 17-4PH Chemistry & Specifications

- Threaded flange features and benefits

17-4 PH threaded flanges are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH threaded flanges yield strength is up over 4 times greater. When compared to Duplex 2205 threaded flanges, the yield strength of 17-4 PH can be up to 2- 1/2 times greater.

17-4 threaded flanges are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below).

Resources: 17-4PH Torque Specs, Flange Dimensions, Flange Bolting Chart

Flange Types Available: Blind Flanges, Lap Joint Flanges, Slip On Flanges, Socket Weld Flanges, Threaded Flanges, Weld Neck Flanges

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, AISI 630, ASTM A564-630, Werkstoff 1.4542, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

This specification covers bars and shapes (such as fasteners) of age hardened stainless steels such as 17-4PH. It includes hot-finished or cold-finished fasteners that are produced by hot rolling, extruding, or forging. Grade 630 shall be furnished in the solution-annealed or or age-hardened condition.

Common 17-4 Threaded Flanges: Aged Conditions vs Tensile Strength

17-4PH Threaded Flange Features & Benefits

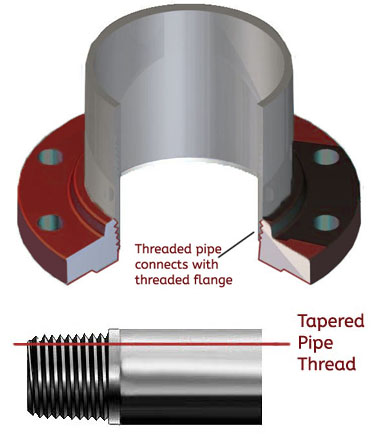

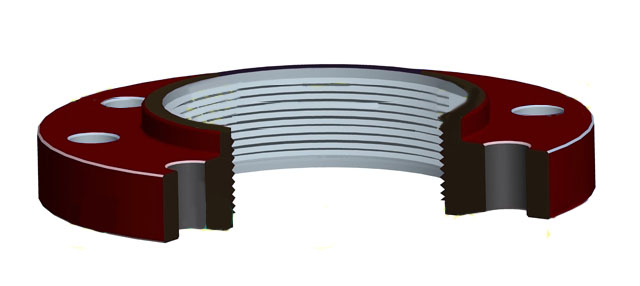

17-4PH threaded flanges have a tapered female thread to join the male threads of a pipe in order to create a tight seal. This type of flange is most ideal when post weld heat treatment is not possible in hazardous, flammable or explosive applications where welding is too dangerous. 17-4PH threaded flanges are also convenient in pilot processes whose configuration is often changed.

Threaded Flange Advangtages

- The main benefit is that that threaded seal eliminates the need for welding.

- As they do not require welding they save time and money to install.

- Allow for connections to be made in dangerous, explosive applications where welding is not possible.

- Useful connection in materials that are difficult to create a successful and strong weld.

- Ideal for connecting small diameter pipes.

- Systems could be easily reconfigured.

Threaded Flange Disadvantages

- They are not suitable where high temperatures, frequent cyclic conditions or bending stresses are likely in applications.

ns.