An engineered stainless steel known for its high yield strength & decent corrosion resistance

An engineered stainless steel known for its high yield strength & decent corrosion resistance

- High Strength - About 2x stronger yield than 316 stainless steel

- Super Duplex - Decent general corrosion & cracking resistance

- Weld Studs available in Duplex 2205 & Duplex 2507

- Features & benefits of Duplex steel weld studs

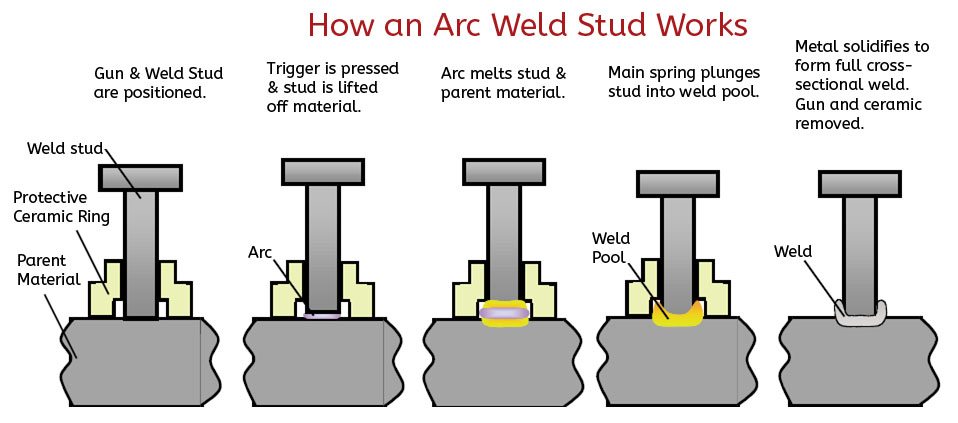

- How a duplex arc weld stud works

- Datasheets for Duplex 2205 and Super Duplex 2507

Duplex steel weld studs are available in a variety of fastener styles for manual (MIG, TIG) arc and capacitor discharge welding methods. Characterized by their high yield strength, which is twice that of the annealed yield strength of typical austenitic stainless steels, Duplex weld studs provide a secure, cross-sectional weld in single-sided access situations for a wide variety of extreme environments. Because of this, Duplex 2205 and Super Duplex 2507 steel are some of the most common grades of duplex used for weld studs with Super Duplex 2507 being the more corrosion resistant grade of the two.

Super Duplex 2507 weld studs' improved corrosion resistance lends itself well to applications prone to stress-corrosion cracking, crevice corrosion, pitting, erosion and general corrosion. Because of the properties of Duplex and Super Duplex stainless steel weld studs are often used in chemical processing, petrochemicals, power industry and seawater equipment.

Usage of both Duplex and Super Duplex steel should be limited to temperatures below 570° F as extended elevated temperature exposure can embrittle this material.

The most common grades of Duplex weld studs are Duplex 2205 and Super Duplex 2507. Gain more insight on these two grades by accessing our Duplex 2205 and Super Duplex 2507 overviews or by contacting our engineering experts.

Resources: Duplex & Super Duplex Torque Specs

Duplex Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Torx Screws

Duplex Steel Weld Stud Features & Benefits

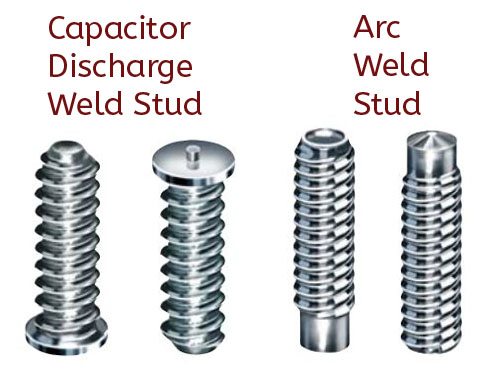

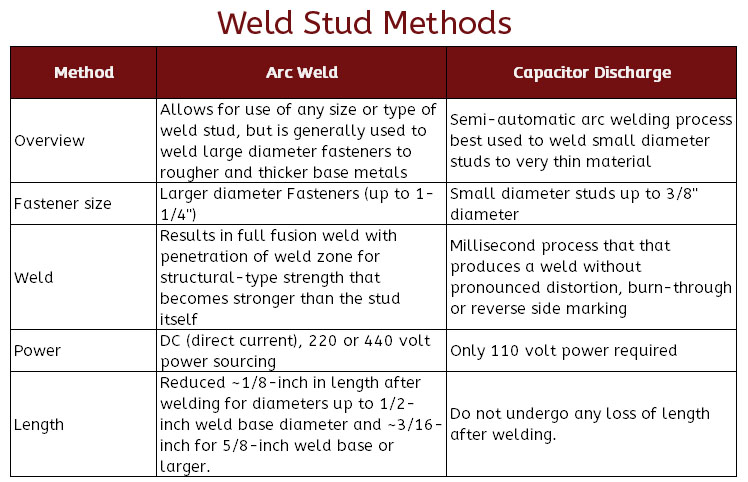

Duplex weld studs available in alloy 2205 and 2507 are an ideal way to securely attached fasteners in extreme applications where reaching both sides of a structure is impossible or undesired. These weld studs can be attached by a variety of welding techniques, such as MIG or TIG welding or they can be attached by automated welding guns using Arc or Capacitor Discharge (CD) technologies.

Arc and Capacitive Discharge (CD) Weld Stud Benefits

Arc and Capacitive Discharge (CD) Weld Stud Benefits

- Security: Unlike the peripheral weld used on a common bolt, the weld used to secure a weld stud fastener is a full cross sectional weld, so the full face of the fastener is welded in place for a strong, secure hold. And since there are no drilled holes – which weakens the structural integrity of the application – the attachment is even stronger.

- Speed: Installing a duplex steel weld stud is a fast and simple process with a most fasteners taking less than 1 second to weld in place. Plus there is no secondary work such as drilling, polishing or grinding.

- Simplicity: Weld studs require almost no special skills and minimal training and equipment is needed for installation. In addition, the equipment is also portable.

- Variety: Duplex and super duplex weld studs are available in a wide variety of fastener styles including (but not limited to) fully threaded, partially threaded, full base, reduced base, long, tapped base, and shoulder thread to name a few.

Duplex Weld Stud Grades, Chemistry & Specifications

Duplex Alloy 2205

Duplex 2205, UNS S32205, is a stainless steel material, whose “Duplex” name is derived from the mixed microstructure which contains roughly equal portions of ferrite and austenite. This grade is the most popular variety and this two-phase material is a significant upgrade from 316 stainless steel in terms of both yield strength and corrosion resistance.

Duplex 2205 Specifications: ASME SA 182, ASME SA 240, ASME SA 479, ASME SA 789, ASME SA 789 Section IV Code Case 2603, ASTM A 240, ASTM A 276 Condition A, ASTM A 276 Condition S, ASTM A 479, ASTM A 790, NACE MR0175/ISO 15156, NORSOK MDS D45 Grade F51, UNS S31803, UNS S32205, W. NR./EN 1.4462, Werkstoff 1.4462 Duplex

Super Duplex Alloy 2507

Super Duplex 2507, UNS S32750, is a two-phase stainless steel and is particularly well suited for use in environments such as warm chlorinated seawater and acidic, chloride containing media. It has similiar properties to Duplex 2205 but is more corrosion resistant and performs well in moderately corrosive environments.

Super Duplex 2507 Specifications: EN 10216-5, ASTM A789; A790, ASTM A182 ASTM A182, ASTM A815, ASTM A240, EN 10088-2, ASTM A479, EN 10088-3 EN 10088, ISO 15156-3, NACE MR0175, Werkstoff 1.4410 S.Duplex

Zeron 100 / F55:

Zeron 100, UNS 32760, is commonly know as F55, which is a slight varient of Super Duplex 2507. This alloy is well suited or seawater applications.

Zeron 100/F55 Specifications: ASTM A 182, ASTM A 182 (Grade F55), ASTM A 240, ASTM A 276, ASTM A 473, ASTM A 479, ASTM A 790, ASTM A 815, ASTM A314, NORSOK MDS 055, UNS S32760, W. Nr./EN 1.4501, Werkstoff 1.4501

Mechanical Data