Q: I have a high pressure application with HCl at fluctuating temperatures. Can you recommend the best flange to provide a safe secure joint?

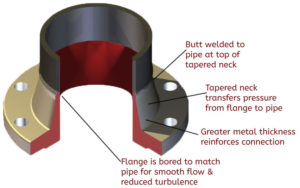

A: Hands down, the weld neck flange is best for these types of hazardous, high pressure applications. Weld neck flanges are easily identified by their long tapered neck which fits over the pipe providing a secure, reinforced connection. The inside of the flange is bored to match the inside diameter of the pipe in order to ensure there is no restriction in flow and also to prevent turbulence at the joint. The tapered neck provides thicker metal at the flange joint, while the neck smooths down gradually to meet the pipe where it is butt welded to the pipe.

This design helps to transfer stress from the flange to the pipe, as well as diminish stress concentration at the base of the flange connection. Weld neck flanges are ideal for critical applications involving high pressure, sub-zero and elevated temperatures, and in conditions where fluctuations cause pipe expansion/contraction.

This design helps to transfer stress from the flange to the pipe, as well as diminish stress concentration at the base of the flange connection. Weld neck flanges are ideal for critical applications involving high pressure, sub-zero and elevated temperatures, and in conditions where fluctuations cause pipe expansion/contraction.

Key Feature: Ideal for High Pressure Applications

Advantages:

o Ability to withstand high pressure – since pipe is welded to the neck of the flange, stress is transferred to the pipe.

o The beveled end that, when connected to a pipe, creates a trough for a strong weld.

o Most versatile flange in the ASME stable of flanges.

Disadvantages:

o More advanced welding skill is needed for installation. The inside weld must be smooth to reduce friction and the outside weld must meet code criteria.

Uses

o Severe conditions that include high-pressure, high-cyclic and hazardous fluid applications.

o Fitting-to-fitting fabrication where the flange is welded directly to a fitting, such as an elbow, without the need for a short piece of pipe, as would be required with a slip-on flange.