316 stainless is a familiar alloy to many of us and perhaps one of the most widely used fastening materials. Though it serves a critical function for industry, 316 can often fall short in servicing challenging high strength, temperature and corrosion resistant applications. Here is how it measures up in these areas against some of the more specialty stainless steel alloys.

316 stainless is a familiar alloy to many of us and perhaps one of the most widely used fastening materials. Though it serves a critical function for industry, 316 can often fall short in servicing challenging high strength, temperature and corrosion resistant applications. Here is how it measures up in these areas against some of the more specialty stainless steel alloys.

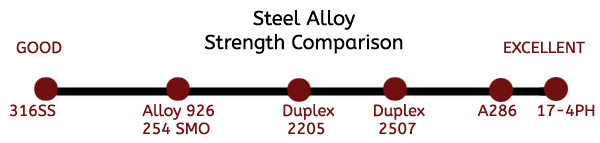

Strength

Compared to many specialty alloyed steels, 316 stainless falls short in terms of strength. Beyond moderate strength options such as duplex steel, extreme steel alloys such as A286 and 17-4PH bolts can provide up to 210ksi of ultimate tensile strength – almost 3x that of a 316 bolt.

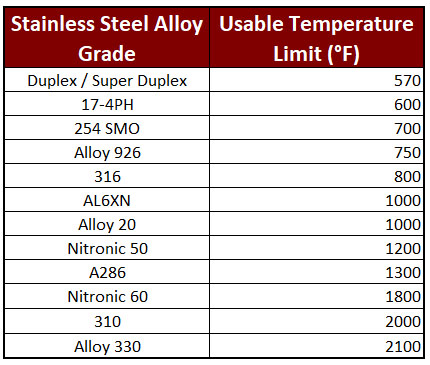

High Temperature

316 stainless steel bolts can be used from subzero to temperatures up to about 800F. Past this limit the mechanical properti

es of the alloy fails and the material can oxidize more rapidly. This falls around the middle of the temperature range of stainless steels, as there are some specialty stainless steels that are temperature sensitive, like duplex steels and 17-4PH, where going beyond 570F or 600F changes the materials characteristics. However, there are a handful heat / oxidation resistant stainless alloys like A286, alloy 310 and alloy 330 provide excellent protection high temperatures up to 2100F. These stainless steels are designed to be temperature stable and oxidation resistant.

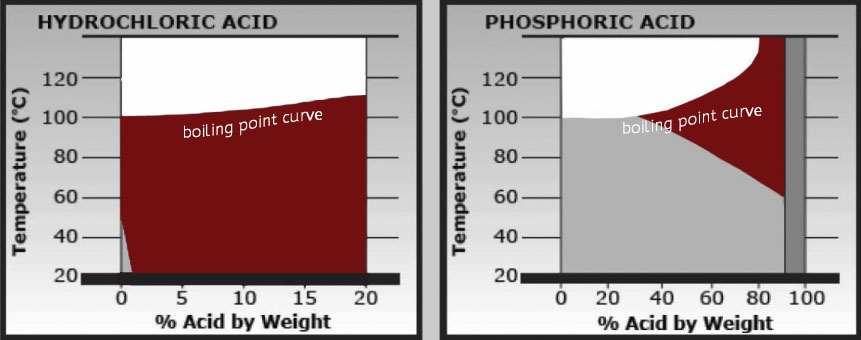

Corrosion

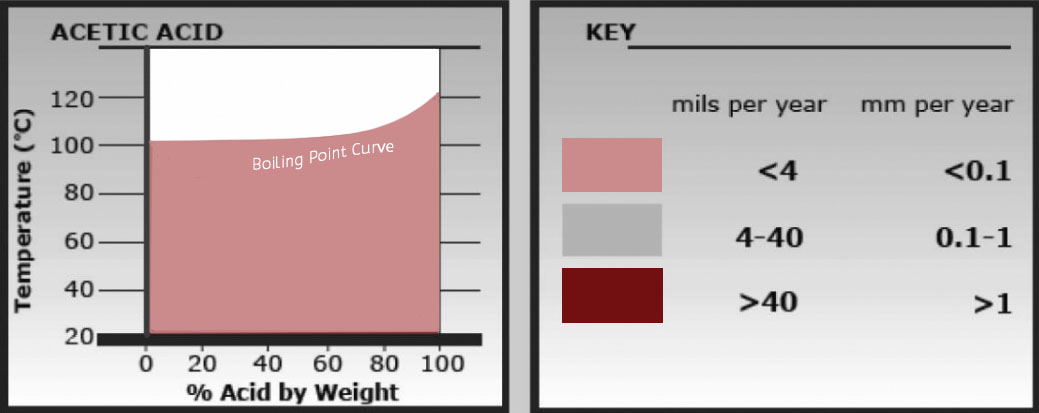

Though 316 doesn’t have the corrosion resistance of a nickel alloy it can perform reasonably well in mild corrosive situations. It is often used for mild resistance to sulfur compounds, acetic acid and phosphoric acid. In contrast, Alloy 20 is a stainless-steel alloy that is designed for corrosion protection and can offer significantly improved corrosive resistance to acids like, acidic acid, sulfuric acid and hydrochloric acid.

316 Hydrochloric Acid Corrosion* 316 Phosphoric Acid Corrosion*

316 Sulfuric Acid Corrosion* 316 Nitric Acid Corrosion*

316 Acetic Acid Corrosion*

*Chart Source: North American Stainless

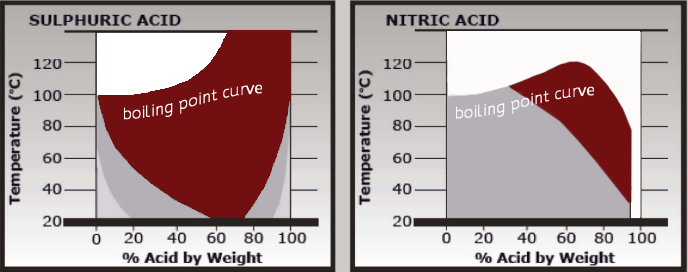

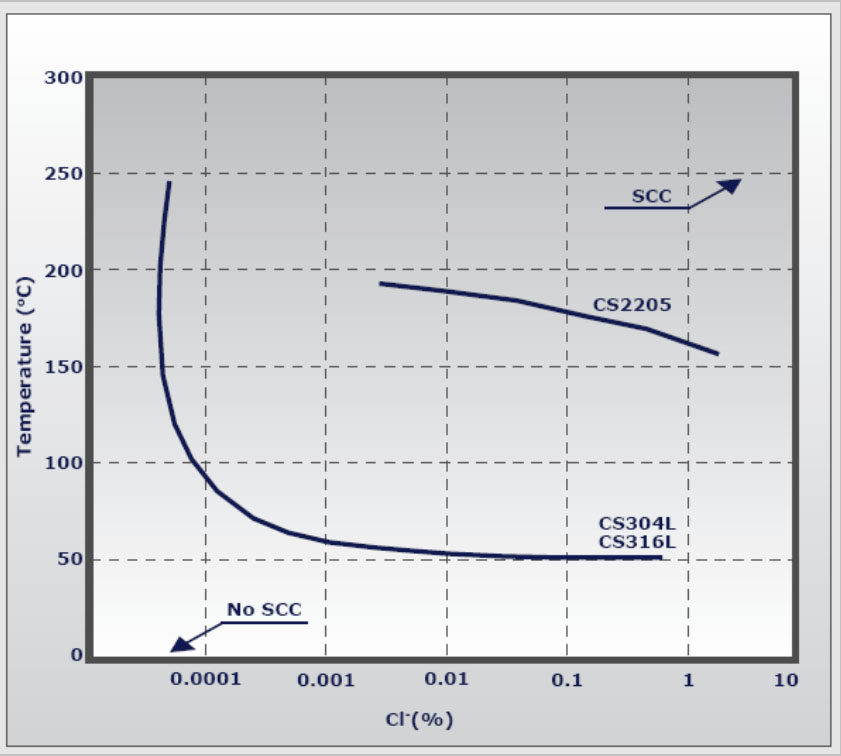

AL6XN (6 Moly Alloy) is another stainless steel alloy developed for salt water environments and is ideal for marine corrosion – a vast improvement in these conditions over 316 bolts. For chlorides and mild saltwater corrosion, duplex and super duplex stainless steel bolts provide significant corrosion performance over 316 bolts. As always, it depends on the exact corrosion environment to determine which stainless steel is best, but for sure, Alloy 20, AL6XN (6 Moly Alloy) and the Duplex steels are optimized for improved corrosion performance over 316 stainless steel.

Chloride Stress Corrosion Cracking: 316 Stainless Steel vs. Duplex 2205*

*Chart Source: North American Stainless