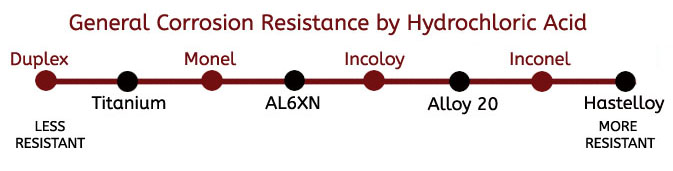

Nickel alloys are a special class of metals containing high levels of nickel (often greater than 20%). They play a key role in industry for their unique combination of high strength, corrosion resistance to harsh acids (like hydrochloric and sulfuric) and high temperature stability. This two-part newsletter will help summarize the distinct benefits of the most common nickel alloys.

Today we’ll focus on Monel, AL6XN, and Alloy 20. These nickel alloys are far more corrosion resistant than stainless steel, but are best used in moderately corrosive conditions that don’t require high performance nickel alloys like Hastelloy. Stay tuned for part 2 which covers high performance nickel alloys for extreme applications.

MONEL

Monel fasteners are most widely used for their resistance to salt water. Perhaps the most unique attribute of Monel is that it can withstand all concentrations of hydrofluoric acid, even up to the boiling point. Monel 400 is ideal for marine and chloride environments, as well as high temperatures, caustic, and salt solution applications. Monel K500 is an age-hardened form of its sister alloy 400, offering similar corrosion resistance with increased strength and hardness.

Mechanical Properties: Monel 400: Yield strength 45 ksi, usable to 1100°F

Monel K500: Yield strength 110 ksi, usable to 1100°F

AL6XN

Mechanical Properties: Yield strength 53ksi; usable to 1000°F

Alloy 20

Alloy 20 fasteners offer improved corrosion resistance to AL6XNand are best known for their performance in hot sulfuric acid – specifically boiling H2SO4 in the range of 20-40% concentration.Alloy 20 screws also provide moderate protection to phosphoric and nitric acid.

Mechanical Properties: Yield strength 35ksi; usable to 1000°F

Chromium & Molybdenum Play Critical Role

In addition to nickel, many of these alloys also contain chromium, molybdenum and iron which enhance their corrosion resistance, strength and high temperature stability. Having a higher chromium content helps to provide resistance to oxidizers and the addition of molybdenum enhances resistance to reducing acids.