A lock nut resists loosening from vibrations and torque. Specialty material lock nuts offer the ideal solution to many extreme applications environments. They combine the unique properties of specialty materials, with the secure locking feature of a lock nut to prevent failures in the field.

One of the most common lock nut styles is a prevailing torque lock nut. This kind of lock nut has a prevailing torque feature which deforms elastically, preventing it from freely spinning like a standard nut.

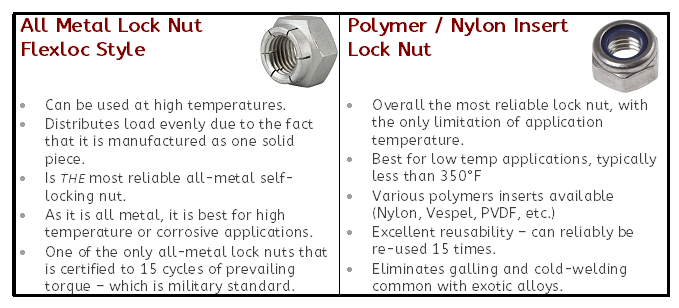

The two most common and reliable forms of prevailing torque lock nuts are the Flexloc style and the polymer insert lock nut. A Flexloc nut is all-metal in composition with a segmented collar that creates six “locking fingers,” that act as a spring. Polymer insert lock nuts are often referred to as nylon insert lock nuts, although various high performance polymers, like PVDF, can be used for the screw threads to “bite into.” Both Flexlock and polymer insert lock nuts are available in both hexagonal and 12 point configurations.

Lock Nuts Secure Real World Solutions

All metal Hastelloy lock nuts are the ideal solution for hot chemical processing environments where hazardous acids are common and vibrating processes can cause fasteners to loosen. They deliver Hastelloy’s corrosion and heat resistance, as well as provide guaranteed locking, which resists loosening in hazardous environments.

Inconel Flexloc for High Temperature Environments

In addition to chemical processing, high temperature applications can create many problems for fasteners as they go through their thermal cycles: constantly expanding/contracting. In these environments, all-metal Inconel lock nuts are very useful in maintaining proper clamping force, as well as preventing loosening from thermal expansion and contraction. Inconel Flexloc nuts provide both, material and fastener security.

17-4 PH Polymer Insert Lock Nuts Deliver Strength

When high temperature or serious corrosion is not a factor, polymer insert lock nuts are an ideal solution for guaranteed fastener security. 17-4PH polymer insert lock nuts are excellent for high strength applications at moderate to low temperatures and usually find themselves on various kinds of mechanical equipment.

clear to know bolt and nuts!

Good to know another type of nut for bolts

Can lock nuts be used in railway fastening system?

What testing do you have that shows the flexloc nut holds well.

Typically for a flexloc style nut the parts are inspected per NASM25027. This spec ensure that the lock nut meets or exceeds the requirements for torque among other things. The NASM25027 testing includes 15 installation and removal cycles with the bolt fully engaging the locking area. This test requires the lock nut to reach the specified prevailing torque for all 15 cycles.

Dean