Specialty stainless fasteners provide industry with temperature stability, strength and corrosion improvements over typical 300 series steels.

Strength

17-4 PH

17-PH fasteners offer excellent high strength and hardness. They are available in the annealed condition or with a variety of age hardening heat treatments that provide different levels of strength ranging from 160-210 ksi UTS.

Duplex Steel

Offering a higher yield strength than 300 series stainless, Duplex fasteners not only offer high strength but also chloride corrosion resistance. They are best in terms of localized chloride corrosion including pitting and crevice corrosion as well as stress corrosion cracking. Available in two grades Duplex 2205 and Super Duplex 2507 which offers slightly higher strength – twice that of 316 stainless.

High Temperature

Alloy 330

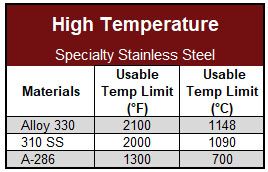

Designed for use in furnace applications, Alloy 330 bolts offer excellent oxidation and carburization resistance at extreme temperatures. Their most prized attribute is their ability to perform under cyclic temperature conditions: from high heat to cooling.

310 Stainless

Similar to Alloy 330, 310 stainless is often used in elevated temperature situations where slightly less strength and heat resistance are required. 310 stainless bolts can be used in moderately carburizing, oxidizing, nitriding, and thermal cycling applications.

A286 / Alloy 660

Though A286 bolts don’t offer quite the heat resistance as 330 or 310, they do offer much higher strength with a minimum ultimate tensile strength up to 160ksi in certain grades. A286 fasteners are typically used for high temperature applications that require both oxidation and creep resistance, as well as superior strength.

Corrosion Resistance

AL6XN

AL6XN bolts were originally developed to combat saltwater corrosion. With higher nickel content than Duplex, they also offer moderate general corrosion resistance, but not to the level of a nickel alloy.

Alloy 20

Suited for moderately corrosive applications, Alloy 20 bolts are best known for their resistance to hot sulfuric acid – specifically to stress corrosion cracking in 20%-40% boiling acid. Alloy 20 fasteners also provide decent stress corrosion cracking, pitting and crevice corrosion resistance in chloride.