Bolt Weight Calculator

Vacuum Gaskets - For Ultra Low Pressure Sealing

Gaskets for vacuum chambers requiring extremely low leak rates

Gaskets for vacuum chambers that minimize leakage are critical in order to maintain the quality of the finished product. No matter if its CVD, PVD, DVD, heat treating etc., maintaining a low vacuum and minimizing oxygen contamination is essential. If having the lowest leak rate is important to your process, our Revolution and JG / JP semi-metallic vacuum gaskets are the best available to industry.

Extremely Low Leak Rate

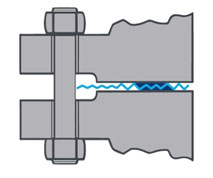

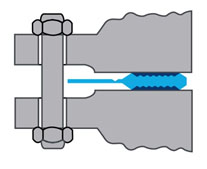

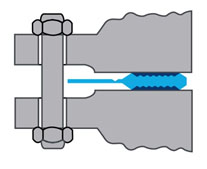

Our semi-metallic vacuum gaskets feature a metallic core which creates metal-to-metal seal as well as as soft sealing PTFE or graphite section. As a result, an extremely tight seal is created, having a leak rate that is 15,000x lower than typical gaskets used in vacuum systems.

No Outgassing

Beyond sealing, our vacuum gaskets will NOT outgas. A key feature to our vacuum gaskets is the metal-to-metal seal that protects and isolates the soft sealing graphite or PTFE from the process and air. Because of this design, no extra time is wasted during pump-down and the desired vacuum is achieved faster.

High Temperature Stability

The JG / JP vacuum gaskets can operate at elevated temperatures up to 1000°C. The Revolution vacuum gaskets up to 500°C

| Revolution Gasket | JG/JP Gasket |

|  |

Parameters

| Parameters

|

Applications

| Applications

|

Advantages

| Advantages

|

High Pressure Gaskets

High pressure gaskets with the lowest leak rate available to industry

Our high pressure gaskets are designed to minimize blowouts and detrimental gasket deformation often found in high pressure applications. Due to Revoseal's unique designs, both the Eco+ and JG / JP gaskets are ideally suited for challenging high pressures, steam hammering, pressure surges and cyclic environments.

If you are having gasket sealing or life issues due to high pressures with spiral wounds, kammprofile, graphite, fiber or PTFE gaskets, the Eco+ or JG / JP gaskets may be ideal.

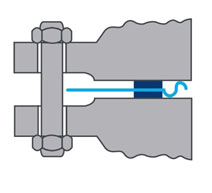

Features a spring like seal which makes an ideal gasket for blowout protection, cyclic pressure applications, and steam hammering.

This is the highest pressure rate gasket offered, and is reserved the the hardest to seal and toughest pressure related applications.

| Eco+ Gasket | JG/JP Gasket |

|  |

Parameters

| Parameters

|

Applications

| Applications

|

Advantages

| Advantages

|